Benefits of Tube Mill Machine

Tube mill machines are an essential tool for many industries. They are used to create pipes and tubing for various applications, including construction, automotive, and manufacturing. These machines are designed to form and shape metal into tubes of various sizes, shapes, and thicknesses.

There are several benefits to using a tube mill machine in the manufacturing process. Here are some of the key advantages:

1. Precision and Accuracy

Tube mill machines are incredibly precise and accurate. They can create tubes with consistent diameters, thicknesses, and lengths, ensuring that every tube produced is of the same high quality. This precision and accuracy are vital for many industries that require uniform products.

2. Efficient Production

Tube mill machines can produce tubes at a high rate, making them an efficient choice for mass production. They can also work around the clock, ensuring that production deadlines are met. The machines are designed to be easy to operate, requiring minimal training, which means that they can be put to work quickly.

3. Versatility

Tube mill machines can produce tubes of various sizes, shapes, and thicknesses. They can also work with different materials, such as steel, aluminum, brass, and copper. This versatility makes them an ideal choice for many industries that require different types of tubing for various applications.

4. Cost-Effective

Tube mill machines are cost-effective, as they can produce large quantities of tubing at a low cost per unit. They also require minimal maintenance, which means that they have a low operating cost. This makes them an ideal choice for companies that need to produce tubing on a large scale while keeping costs down.

5. Customizable

Tube mill machines can be customized to meet the specific needs of a particular industry or application. They can be designed to produce tubes of a particular size, shape, or thickness, making them an ideal choice for companies that require custom tubing.

In conclusion, tube mill machines are an essential tool for many industries. They offer precision, accuracy, efficiency, versatility, cost-effectiveness, and customization, making them an ideal choice for companies that need to produce high-quality tubing on a large scale. With the benefits of tube mill machines, companies can improve their production processes, increase efficiency, and reduce costs.

Features of Tube Mill Machine

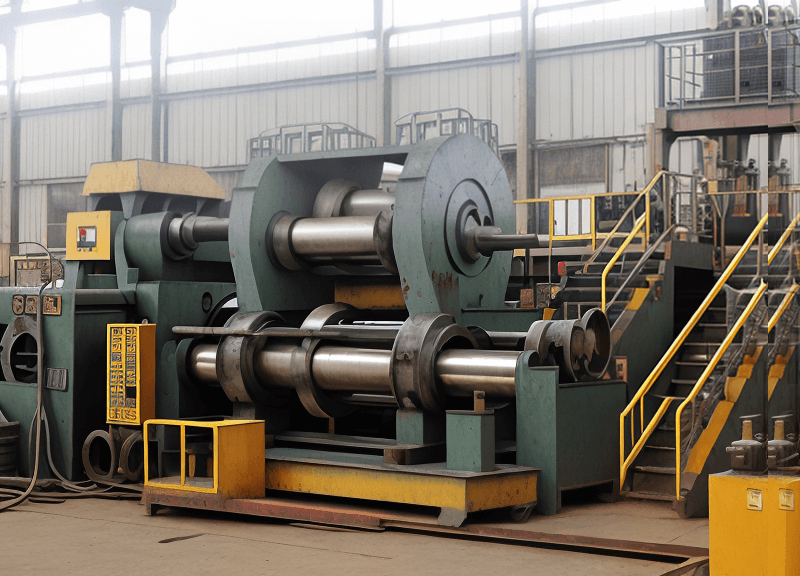

A tube mill machine is a device used in the production of pipes and tubes. It is a versatile machine that is used in various industries such as construction, automotive, and oil and gas. It is a cylindrical machine that uses a series of rollers to form a metal tube from a flat strip of metal. The machine is composed of several key features that make it an effective tool for tube production.

One of the key features of the tube mill machine is the uncoiler. This is a device that holds the metal strip and feeds it into the machine. It is designed to handle large and heavy coils of metal, and it can be adjusted to accommodate different widths of metal strips. The uncoiler is an essential part of the machine as it ensures that the metal strip is fed into the machine at a constant speed.

Another important feature of the tube mill machine is the strip joiner. This is a device that joins the end of one metal strip to the beginning of another. It is essential to have a continuous supply of metal strip to the machine to ensure that the tube production is not interrupted. The strip joiner is designed to join the strips seamlessly, ensuring that there is no defect in the final product.

The forming section is another important feature of the tube mill machine. This is the section where the metal strip is formed into a tube. It is composed of a series of rollers that gradually bend the metal strip into a tube shape. The rollers can be adjusted to produce tubes of different sizes and shapes. The forming section is designed to ensure that the tube is formed with precision and accuracy.

The welding section is where the two edges of the metal strip are welded together to form a continuous tube. The welding process is done using either high-frequency welding or TIG welding. The welding section is designed to ensure that the weld is strong and durable, ensuring that the tube will not break or leak.

The sizing section is the final section of the tube mill machine. This is where the tube is sized to the required dimensions. The sizing section is composed of a series of rollers that compress the tube to the required diameter. The sizing section is designed to ensure that the tube is sized accurately and consistently.

In conclusion, the tube mill machine is a versatile machine that is used in various industries for tube production. It is composed of several key features that make it an effective tool for tube production. The uncoiler, strip joiner, forming section, welding section, and sizing section are all essential parts of the machine. They work together to ensure that the tube is produced with precision and accuracy.

Tube Mill Machine Specifications

Types of Tube Mill Machine

Tube mills are machines that are widely used in the manufacturing industry for shaping and forming metal tubes. These machines are used for a variety of purposes and are available in various types to cater to different manufacturing needs. In this article, we will explore some of the most common types of tube mill machines.

1. ERW Tube Mill Machine

ERW stands for Electric Resistance Welding, which is a process that is used to join two pieces of metal. ERW tube mill machines use this process to produce tubes that are used in a wide range of applications. These machines are known for their high efficiency and can produce tubes of different sizes and thicknesses.

2. HF Tube Mill Machine

High-frequency (HF) tube mill machines are another popular type of tube mill machine. These machines use high-frequency energy to heat and weld metal tubes. They are used to produce tubes of various shapes and sizes, and they are known for their high speed and accuracy.

3. TIG Welded Tube Mill Machine

TIG (Tungsten Inert Gas) welding is a process that is used to join two pieces of metal using a non-consumable tungsten electrode. TIG welded tube mill machines are used to produce high-quality tubes that are used in a range of industries, including aerospace and automotive. These machines are known for their precision and accuracy.

4. Seamless Tube Mill Machine

Seamless tube mill machines are used to produce seamless tubes that are used in a variety of applications, including oil and gas, automotive, and aerospace. These machines use a process called cold drawing, which involves pulling the metal through a die to create a seamless tube.

5. Welded Stainless Steel Tube Mill Machine

Stainless steel is a popular material used in various industries, including food processing, medical, and automotive. Welded stainless steel tube mill machines are used to produce tubes made of stainless steel. These machines use a range of welding processes, including TIG and plasma welding, to produce high-quality tubes.

In conclusion, tube mill machines are an essential part of the manufacturing industry. They are used to produce tubes of different sizes and shapes, and they are available in various types to cater to different manufacturing needs. Whether you need to produce tubes for the automotive industry or the aerospace industry, there is a tube mill machine that can meet your requirements.

Applications of Tube Mill Machine

Tube mill machines are a type of industrial equipment that are used to produce tubes or pipes of various shapes and sizes. These machines are widely used in various industries, including construction, oil and gas, automobile, and aerospace. Tube mill machines come in different types, sizes, and designs and can be used for various applications. In this article, we will discuss the applications of tube mill machines in various industries.

Construction Industry:

Tube mill machines are widely used in the construction industry for manufacturing pipes, tubes, and hollow sections. These pipes and tubes are used in different applications such as building structures, bridges, and tunnels. Tube mill machines can produce pipes and tubes of various shapes and sizes, including round, square, and rectangular. These pipes and tubes are made from different materials such as steel, aluminum, and copper. Tube mill machines are also used for manufacturing scaffolding pipes that are used in the construction of buildings.

Oil and Gas Industry:

Tube mill machines are widely used in the oil and gas industry for manufacturing pipes that are used for transporting oil and gas. These pipes are made from high-quality materials that can withstand high pressure and temperatures. Tube mill machines can produce pipes of various sizes and shapes that are used in different applications such as drilling, transportation, and storage. These pipes are also used in the construction of oil rigs and pipelines.

Automobile Industry:

Tube mill machines are widely used in the automobile industry for manufacturing exhaust pipes and other components. These pipes are made from stainless steel or other high-quality materials that can withstand high temperatures and corrosive environments. Tube mill machines can produce pipes of various shapes and sizes that are used in different applications such as exhaust systems, fuel systems, and air conditioning systems.

Aerospace Industry:

Tube mill machines are used in the aerospace industry for manufacturing tubes and pipes that are used in aircraft and spacecraft. These tubes and pipes are made from high-quality materials such as titanium and aluminum that can withstand extreme temperatures and pressures. Tube mill machines can produce tubes and pipes of various sizes and shapes that are used in different applications such as fuel systems, hydraulic systems, and air conditioning systems.

In conclusion, tube mill machines are widely used in various industries for manufacturing pipes and tubes of different shapes and sizes. These machines are essential for producing high-quality pipes and tubes that are used in different applications such as construction, oil and gas, automobile, and aerospace. Tube mill machines come in different types, sizes, and designs and can be customized to meet the specific requirements of different industries.

Selecting the Ideal Tube Mill Machine Manufacturer

Tube mill machines are essential in the manufacturing industry as they are used to produce high-quality steel tubes for various applications. They come in different shapes and sizes, and they can be customized to meet specific production needs. However, selecting the ideal tube mill machine manufacturer can be a daunting task. There are many factors to consider, including the quality of the machine, customer service, pricing, and delivery time. In this article, we will explore the key factors that you should consider when selecting a tube mill machine manufacturer.

Quality of the Machine

The quality of the tube mill machine is the most crucial factor to consider when selecting a manufacturer. The machine should be made of high-quality materials and should be designed to withstand harsh working conditions. A good tube mill machine should also be easy to operate and maintain. You should look for a manufacturer that has a reputation for producing high-quality machines.

Customer Service

Customer service is another crucial factor to consider when selecting a tube mill machine manufacturer. You want to work with a manufacturer that is responsive to your needs and can provide timely support when you need it. The ideal manufacturer should have a team of experts who can help you with any questions or issues you may have. They should also be willing to provide training and after-sales support to ensure that you get the most out of your machine.

Pricing

Pricing is always a factor when selecting any product, and tube mill machines are no exception. You want to work with a manufacturer that offers competitive pricing without compromising on quality. However, you should avoid manufacturers who offer significantly lower prices than their competitors as this may indicate low-quality machines.

Delivery Time

The delivery time of the tube mill machine is also an important factor to consider. You want to work with a manufacturer that can deliver the machine within the agreed-upon timeframe. Delayed delivery can cause significant disruptions to your production process, leading to lost revenue and increased costs.

Conclusion

Selecting the ideal tube mill machine manufacturer requires careful consideration of multiple factors. You should look for a manufacturer that produces high-quality machines, offers excellent customer service, competitive pricing, and timely delivery. At the end of the day, you want to work with a manufacturer that can provide you with a reliable and efficient machine that meets your production needs. With these factors in mind, you can select the ideal tube mill machine manufacturer for your business.

Process of Tube Mill Machine

Tube mill machines are used to manufacture and produce pipes and tubing for a wide range of applications. The process of tube mill machine involves several steps, starting from the raw material to the finished product. In this article, we will take a closer look at the process of tube mill machines.

1. Raw Material

The first step in the process of tube mill machines is to select the raw material. The most common materials used are steel and aluminum. The raw material is then loaded onto the machine and fed through the rollers.

2. Forming

The next step is forming the raw material into the desired shape. The tube mill machine has a series of rollers that gradually bend and shape the raw material into a tube. The size and shape of the tube can be adjusted by changing the settings on the machine.

3. Welding

Once the raw material has been formed into a tube, the next step is welding. The tube mill machine uses high-frequency induction welding to join the edges of the tube together. This creates a strong, seamless weld that is virtually invisible.

4. Cutting

After the welding process is complete, the tube is cut to the desired length. The tube mill machine has a cutting blade that can be adjusted to cut the tube to the exact length required.

5. Finishing

The final step in the process of tube mill machines is finishing. This involves removing any rough edges or burrs from the tube and polishing it to a smooth finish. This makes the tube ready for use in a wide range of applications.

In conclusion, the process of tube mill machines is a complex and multi-step process that involves selecting the raw material, forming it into a tube, welding the edges together, cutting it to the desired length, and finishing it to a smooth surface. Tube mill machines are critical in the production of tubes and pipes for a wide range of applications, including construction, automotive, and manufacturing.

list FAQ with answer about Tube Mill Machine

Tube mill machines are used in the manufacturing of tubes by welding or rolling metal sheets. These machines are used in various industries such as construction, automotive, and manufacturing. If you are considering purchasing a tube mill machine, you may have some questions about their use and functionality. Here are some frequently asked questions with answers about tube mill machines.

1. What is a tube mill machine?

A tube mill machine is a machine used to manufacture tubes by welding or rolling metal sheets. It is used in various industries such as construction, automotive, and manufacturing.

2. What are the types of tube mill machines?

There are various types of tube mill machines such as ERW (Electric Resistance Welding) tube mill machines, HF (High-Frequency) tube mill machines, and TIG (Tungsten Inert Gas) welding tube mill machines.

3. What are the advantages of tube mill machines?

Tube mill machines offer various advantages such as high production speed, high accuracy, and the ability to produce tubes of various shapes and sizes. They are also cost-effective and require less labor.

4. What are the applications of tube mill machines?

Tube mill machines are used in various industries such as construction, automotive, and manufacturing. They are used to manufacture tubes for structural purposes, exhaust systems, heat exchangers, and pressure vessels.

5. What is the capacity of tube mill machines?

The capacity of tube mill machines varies depending on the type and model of the machine. Generally, they can produce tubes of various sizes and thicknesses.

6. What is the maintenance required for tube mill machines?

Tube mill machines require regular maintenance to ensure their smooth functioning. This includes cleaning, lubrication, and regular inspection of the machine parts.

7. What is the cost of a tube mill machine?

The cost of a tube mill machine varies depending on the type, model, and capacity of the machine. Generally, they are cost-effective and offer a good return on investment.

In conclusion, tube mill machines are an important part of various industries and offer various advantages such as high production speed, high accuracy, and the ability to produce tubes of various shapes and sizes. If you are considering purchasing a tube mill machine, it is important to understand their use and functionality. The above FAQ with answers should provide you with a basic understanding of tube mill machines.

Tube Mill Machine Price

Tube mill machines are essential equipment for the production of various types of pipes, including seamless, welded, and galvanized pipes. These machines are used in a wide range of industries, such as construction, automotive, and oil and gas. If you’re planning to invest in a tube mill machine, one of the most important factors to consider is the price.

The price of a tube mill machine varies depending on several factors. These include the machine’s capacity, specifications, and features. Generally, higher-capacity machines with advanced features are more expensive than smaller, basic models. Additionally, brand reputation and customer support also affect the price.

On average, the price of a tube mill machine ranges from $50,000 to $500,000. However, it’s important to note that the price can go up or down depending on the aforementioned factors. Some suppliers may offer financing options that allow you to pay for the machine in installments.

When comparing prices, it’s important to consider the quality of the machine, as well as the supplier’s reputation and customer support. Choosing a high-quality machine from a reputable supplier can save you money in the long run, as it will require less maintenance and repair.

Another factor to consider when purchasing a tube mill machine is the cost of operation. This includes expenses such as electricity, labor, and raw materials. It’s important to calculate these costs to ensure that the machine is cost-effective and profitable for your business.

In conclusion, the price of a tube mill machine varies depending on several factors, including capacity, specifications, features, brand reputation, and customer support. When purchasing a tube mill machine, it’s important to consider the quality of the machine, as well as the cost of operation. By doing so, you can make an informed decision and invest in a machine that will help your business grow and succeed.