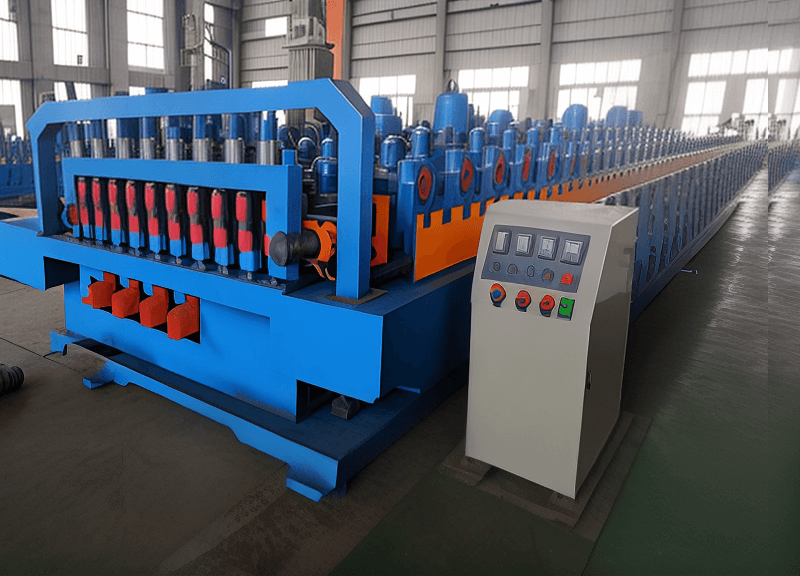

Roll Forming Machine Manufacturing for importer customize design, wholesale

Roll Forming Machine

The Roll Forming Machine is a versatile and highly efficient industrial tool that is designed for creating complex and precise metal shapes from flat sheets of metal. This machine is widely used in various industries, including automotive, construction, and manufacturing, for producing high-quality components and parts with exceptional accuracy and speed.

Benefits:

– High Precision: The Roll Forming Machine is capable of producing complex and precise metal shapes with exceptional accuracy.

– Increased Efficiency: This machine can produce parts at high speeds, resulting in increased productivity and reduced manufacturing costs.

– Versatility: The Roll Forming Machine can be used to produce a wide range of metal shapes and components, making it a highly versatile industrial tool.

– Low Maintenance: This machine requires minimal maintenance, which reduces downtime and maintenance costs.

Features:

– Robust Construction: The Roll Forming Machine is made of high-quality materials and features a robust construction that ensures durability and longevity.

– Easy to Operate: This machine is user-friendly and easy to operate, requiring minimal training.

– Customizable: The Roll Forming Machine can be customized to meet specific manufacturing requirements and produce unique shapes and components.

– Automated: This machine features automated processes that reduce manual labor and improve manufacturing efficiency.

Applications:

– Automotive Industry: The Roll Forming Machine is used in the production of automotive components, such as door frames, roof rails, and chassis parts.

– Construction Industry: This machine is used for producing structural components, such as beams, columns, and trusses.

– Manufacturing Industry: The Roll Forming Machine is used for producing a wide range of metal components, such as electrical enclosures, furniture frames, and industrial equipment parts.

FAQ:

Q: What materials can be used with the Roll Forming Machine?

A: The Roll Forming Machine can be used with a range of metals, including steel, aluminum, and copper.

Q: What is the maximum thickness and width of the metal sheets that can be used with this machine?

A: The maximum thickness is 3 mm, and the maximum width is 1,500 mm.

Q: How many roller stations does the Roll Forming Machine have?

A: The number of roller stations can range from 10 to 30.

Roll Forming Machine

Benefits of Roll Forming Machine

Roll forming is a process used in the manufacturing of metal products. It is a continuous bending operation where a long strip of metal is passed through a series of rollers to form the desired shape. Roll forming machines are used in this process and have become an essential tool in the metalworking industry. The benefits of roll forming machines are numerous, making them a popular choice for manufacturers.

One of the main benefits of using a roll forming machine is that it can produce high-quality metal products with consistent accuracy. The rollers in the machine can be adjusted to create the exact shape and dimension required, resulting in precise and uniform products. This level of precision is difficult to achieve with other metalworking methods, making roll forming an attractive option for manufacturers who need reliable and consistent results.

Roll forming machines are also very versatile, capable of producing a wide range of metal products such as roof panels, gutters, and structural components. The flexibility of the machines means that they can handle a range of materials, including steel, aluminum, copper, and more. This versatility makes roll forming machines an ideal choice for manufacturers who need to produce different products or have changing production requirements.

Another significant benefit of using a roll forming machine is its efficiency. The continuous bending process allows for high-speed production, reducing manufacturing time and costs. Additionally, the machines require minimal labor, as they are often automated, and can operate for extended periods without stopping. This means manufacturers can produce high-quality metal products quickly, efficiently, and at a lower cost.

Roll forming machines are also known for their durability and reliability. They are built to withstand high levels of stress and have a long lifespan, making them a sound investment for manufacturers. The machines can operate in harsh environments and conditions, and they require minimal maintenance, reducing downtime and increasing productivity.

In conclusion, the benefits of roll forming machines are numerous, making them a popular choice for manufacturers. The machines can produce high-quality metal products with consistent accuracy, are versatile and efficient, and are durable and reliable. With these benefits, it is no wonder that roll forming machines have become an essential tool in the metalworking industry, helping manufacturers to produce quality products quickly and cost-effectively.

Features of Roll Forming Machine

Roll forming machines are a popular type of metalworking machinery that has revolutionized the way metal products are produced. These machines are widely used in a variety of industries, including construction, automotive, and manufacturing. They are designed to shape metal into a desired cross-section by passing it through a series of rollers.

Here are some of the key features of roll forming machines:

1. Flexibility

One of the biggest advantages of roll forming machines is their flexibility. They can be used to produce a wide range of metal products, from simple shapes to complex profiles. This makes them ideal for a variety of applications, including roofing, siding, and window frames.

2. High Production Speeds

Roll forming machines are capable of producing large quantities of metal products at high speeds. This makes them ideal for mass production applications where efficiency and productivity are critical.

3. Low Tooling Costs

Roll forming machines have relatively low tooling costs compared to other metalworking machinery. This is because they use a series of rollers to shape the metal, rather than expensive dies and molds. This makes them a cost-effective option for small to medium-sized manufacturers.

4. Consistent Quality

Roll forming machines are designed to produce metal products with consistent quality. This is because the process is highly automated, and the machines are equipped with sensors and other monitoring systems to ensure that the metal is shaped correctly.

5. Easy Maintenance

Roll forming machines are relatively easy to maintain, with most models requiring only basic maintenance tasks such as cleaning and lubrication. This means that they can be operated with minimal downtime, which is essential for manufacturers who need to maximize their productivity.

In conclusion, roll forming machines are a versatile and cost-effective option for manufacturers who need to produce high-quality metal products at high speeds. With their flexibility, high production speeds, low tooling costs, consistent quality, and easy maintenance, they are an essential piece of equipment for many industries.

- Coil width: 350mm

- Output speed: 15-20m/min

- Thickness range of applicable color steel sheet: 0.3mm-0.8mm

- Tolerance: ±1.5mm within 3 meters

- Number of roller stations: 14

- Main motor power: 4Kw

- Hydraulic oil pump motor: 3Kw, with hydraulic pressure of 12Mpa

- Frequency inverter: Panasonic brand

- Computer control system: Equipped with PLC system for controlling length; uses OMRON encoder and custom Schneider button for operation

- Roller diameter: Ф56mm

- Roller material: Made of Gcr15 steel

- Cutter material: Made of Cr12Mov steel with HRC58-62 heat treatment and chrome coating

- Transmission type: Equipped with 1-inch single chain drive

- Dimensions (LWH): Approximately 6500mm x 1000mm x 1200mm

Please note that the actual price of this machine may vary depending on various factors such as location, supplier, and other specific requirements. It is recommended to consult with a local supplier or search online to obtain the most accurate and up-to-date pricing information.

Types of Roll Forming Machine

Roll forming is a process used to shape metal coils into a specific shape or design that is commonly used in the manufacturing industry. This process is often used to create a wide range of products such as automotive parts, roofing materials, and building components. Roll forming machines are designed to handle this process, and there are many different types available to suit a variety of needs.

Here are some of the most common types of roll forming machines:

1. Single Station Roll Forming Machines

Single station roll forming machines are commonly used for low-volume production runs. These machines are designed to produce a specific profile or shape, and they are often used for creating custom parts or prototypes. Single station machines are typically less expensive than other types of roll forming machines, making them a popular choice for small businesses or individuals.

2. Multi-Station Roll Forming Machines

Multi-station roll forming machines are designed for high-volume production runs. These machines are equipped with multiple stations that can produce different profiles or shapes simultaneously. This allows for faster production times and increased efficiency. Multi-station machines are often used in large factories or manufacturing plants.

3. Duplex Roll Forming Machines

Duplex roll forming machines are similar to multi-station machines, but they are designed to produce two or more profiles simultaneously. These machines are often used in the production of automotive parts, where multiple parts need to be produced at the same time.

4. Custom Roll Forming Machines

Custom roll forming machines are designed to produce specific profiles or shapes that cannot be produced using standard machines. These machines are often used in the production of specialized products, such as custom roofing materials or unique building components.

5. Portable Roll Forming Machines

Portable roll forming machines are designed to be moved from one job site to another. These machines are commonly used in the construction industry, where they can be used to produce custom metal components on site. Portable roll forming machines are typically smaller than other types of roll forming machines, making them easier to transport and set up.

In conclusion, roll forming machines are an essential part of the manufacturing industry, and there are many different types available to suit a variety of needs. Whether you are looking for a machine for low-volume production runs or high-volume manufacturing, there is a roll forming machine out there that can meet your needs. With the right machine, you can produce high-quality metal components quickly and efficiently, helping you to grow your business and stay competitive in today’s market.

Applications of Roll Forming Machine

Roll forming machines have been used in various industries for many years. These machines are designed to bend and shape metal strips into a specific shape or profile. The machine works by feeding a metal strip through a series of rollers, which gradually bend the strip until it reaches the desired shape. The process is continuous and can produce large quantities of metal components with consistent accuracy. In this article, we will explore the different applications of roll forming machines.

1. Construction Industry

Roll forming machines are widely used in the construction industry for producing metal components such as roofing, wall cladding, gutters, and downpipes. These components are essential for any building and require high precision and accuracy to ensure a proper fit. Roll forming machines can produce these components in large quantities, making them ideal for the construction industry.

2. Automotive Industry

The automotive industry also uses roll forming machines for producing various metal components such as bumper beams, door frames, and roof rails. These components require high strength and durability, which can be achieved through the roll forming process. Roll forming machines can produce these components with high precision and consistency, ensuring they meet the required specifications.

3. Electrical Industry

The electrical industry also uses roll forming machines for producing metal components such as cable trays, conduit pipes, and busbars. These components are essential for electrical installations and require high precision and accuracy. Roll forming machines can produce these components in large quantities, making them ideal for the electrical industry.

4. Furniture Industry

The furniture industry also uses roll forming machines for producing metal components such as chair frames, table legs, and shelving units. These components require high precision and accuracy to ensure a proper fit and strength. Roll forming machines can produce these components in large quantities, making them ideal for the furniture industry.

5. Agricultural Industry

The agricultural industry also uses roll forming machines for producing metal components such as grain bins, silos, and livestock shelters. These components require high strength and durability to withstand harsh weather conditions and heavy loads. Roll forming machines can produce these components with high precision and consistency, ensuring they meet the required specifications.

In conclusion, roll forming machines have various applications in different industries. These machines offer a cost-effective and efficient method of producing metal components with high precision and consistency. The versatility of roll forming machines makes them ideal for various industries, including construction, automotive, electrical, furniture, and agricultural. With the continuous advancement of technology, roll forming machines are expected to become even more efficient and versatile in the future.

Selecting the Ideal Roll Forming Machine Manufacturer

Roll forming machines are essential equipment for producing metal products such as roofing sheets, wall panels, and floor decking. Their precision and efficiency are crucial in achieving high-quality output, and selecting the right manufacturer is critical to the success of any metal fabrication business. In this article, we will discuss the key factors to consider when selecting the ideal roll forming machine manufacturer.

1. Quality of machines

The quality of the roll forming machines is the most crucial factor to consider. The ideal manufacturer should use high-quality materials and advanced technology to produce machines that are durable, efficient, and reliable. You can also check for certifications such as ISO 9001:2015 or CE to ensure that the machines meet international standards.

2. Experience and reputation

Experience and reputation are also essential factors to consider. A manufacturer with a long history of producing roll forming machines is likely to have more knowledge and skills in the industry. You can also check for reviews and testimonials from previous clients to gauge their reputation in the market.

3. Customization options

The ideal manufacturer should offer customization options to meet specific production needs. This way, you can have machines that are tailored to your requirements, which can save you time and money.

4. Technical support and after-sales service

Technical support and after-sales service are also essential factors to consider. The ideal manufacturer should offer adequate technical support during installation and commissioning of the machines. They should also provide training on machine operation and maintenance. Additionally, they should have a reliable after-sales service to provide repairs and spare parts in case of breakdowns.

5. Price and payment terms

Price is also a crucial factor to consider. However, it should not be the only factor to consider when selecting the ideal manufacturer. You should also check the payment terms, such as down payment, delivery time, and payment schedule, to ensure that they are favorable to your business.

In conclusion, selecting the ideal roll forming machine manufacturer is critical to the success of your metal fabrication business. You should consider factors such as quality, experience, customization options, technical support, after-sales service, and price when making your decision. By choosing the right manufacturer, you can ensure that you have reliable and efficient machines that meet your production needs.

FAQ about Roll Forming Machine

Roll Forming Machines are widely used in various industries such as automotive, construction, and manufacturing. These machines form metal sheets into specific shapes and sizes through a continuous bending process. If you are looking to purchase a Roll Forming Machine, it’s important to understand how they work, what features they have and how to maintain them. Here are some frequently asked questions about Roll Forming Machines:

1. What is a Roll Forming Machine?

A Roll Forming Machine is a piece of equipment that creates uniform and precise shapes out of metal sheets. The machine uses a series of rollers to bend the metal sheet into the desired shape. The machine can produce different shapes and sizes depending on the dies used.

2. What materials can be used with a Roll Forming Machine?

Roll Forming Machines can work with a variety of materials such as steel, aluminum, copper, and brass. They can also work with different gauges of metal depending on the machine’s capabilities.

3. What are the benefits of using a Roll Forming Machine?

Roll Forming Machines have several benefits, including high productivity, accuracy, and efficiency. They can produce uniform shapes with consistent quality, making them ideal for mass production. Additionally, they are versatile and can be used for various applications.

4. What factors should be considered when selecting a Roll Forming Machine?

When selecting a Roll Forming Machine, consider the type of material you will be working with, the maximum width and thickness of the material, and the desired shape and size of the finished product. Also, consider the machine’s speed, accuracy, and ease of use.

5. How do you maintain a Roll Forming Machine?

To maintain a Roll Forming Machine, regular cleaning and lubrication are essential. Check the machine’s rollers and bearings for wear and tear, and replace them as needed. Also, ensure that the machine’s electrical connections and safety features are functioning correctly.

6. How can you ensure safety when working with a Roll Forming Machine?

To ensure safety when working with a Roll Forming Machine, follow all safety guidelines provided by the manufacturer. Wear protective gear such as gloves, safety glasses, and earplugs. Also, ensure that the machine is properly grounded and that all electrical connections are secure.

In conclusion, Roll Forming Machines are essential pieces of equipment for various industries. By understanding how they work and how to maintain them, you can ensure that your machine is operating efficiently and safely. When selecting a Roll Forming Machine, consider your specific needs and the machine’s capabilities to ensure that you get the best results.

Roll Forming Machine Price

Roll forming is a manufacturing process that has been around for many years. It involves the continuous bending of a metal strip into a desired shape using a series of rollers. Roll forming machines are essential equipment for this process, and they come in different sizes and designs. The roll forming machine price varies depending on several factors, including the type of machine, its specifications, and the manufacturer.

The cost of a roll forming machine can range from a few thousand dollars to hundreds of thousands of dollars. The most basic and affordable machines are manual or semi-automatic and can handle simple profiles. These machines have limited capabilities and are suitable for small-scale production of simple shapes. The price of a basic roll forming machine can range from $5,000 to $20,000.

On the other hand, fully automatic roll forming machines can handle complex profiles and high-volume production. They are equipped with advanced features such as computerized controls, automatic material feeding, and cutting systems. These machines are more expensive than the basic models, and their prices can range from $50,000 to $500,000 or more.

The specifications of a roll forming machine also affect its price. Larger machines with wider rollers and more robust frames are more expensive than smaller machines. The thickness of the material that the machine can handle also affects its price. Machines that can handle thicker and stronger materials require more power and have more robust components, which makes them more expensive.

The manufacturer is another factor that affects the price of a roll forming machine. Established and reputable manufacturers with a long history of producing high-quality machines tend to charge more than newer or lesser-known manufacturers. However, choosing a reliable and established manufacturer is essential to ensure the durability and reliability of the machine.

In addition to the initial cost of the machine, other factors such as maintenance, repair, and operating costs should also be considered when calculating the total cost of ownership. Machines that require frequent maintenance or have a high rate of breakdowns can quickly become expensive to operate and maintain. Therefore, it is essential to choose a machine that is durable, reliable, and easy to maintain.

In conclusion, the roll forming machine price varies depending on several factors, including the type of machine, its specifications, and the manufacturer. While the cost of the machine is an essential consideration, other factors such as reliability, durability, and operating costs should also be considered. Ultimately, choosing a high-quality machine that meets your production needs and budget is crucial for the success of your business.

Related products

laser machine

food machinery

©2023. sourcifychina.com All Rights Reserved.

-

- Home

- Retail Cheap Shop

- Wholesale Featured Pro

- Industries

- List

- Our China Suppliers list

- Auto Parts Suppliers

- Packaging Solution

- Stainless Steel Suppliers

- Steel Pipe Suppliers

- Solar Inverter China

- cable manufacturing

- cnc machining China

- Apparel and Accessories

- fabric manufacturing

- Machinery

- pump China

- Screw

- wigs custom

- valves manufacturing

- hair system custom

- heated gloves wholesale

- indoor lighting fixtures

- solor panel wholesale

- snow boots factory

- Products

- Manufacturing

- Guide

- Apparel / Fashion Accessories

- CNC Tools Valve Pump Parts

- Machinery China Equiment Sourcing Guide

- aac block manufacturers

- acrylic cutting machine

- automatic packing machine

- Auxiliary Equipment

- blister packing machine

- bricks manufacturing

- clay brick making machine

- feed pellet machine

- fly ash bricks machine sourcing guide

- paper bag making machine

- pellet machine

- plastic crusher machine

- pouchpacking machine

- stamping machine

- wood pellet machine

- Outdoor Sports

- Others Sourcing Guide

- FAQ

- About

- Contact

- Login

- Newsletter

- [email protected] whatsapp 8615951276160

- 供应商

Login

- →

- WeChat: 8615951276160