List Technical Parameters of “aluminum coil China”

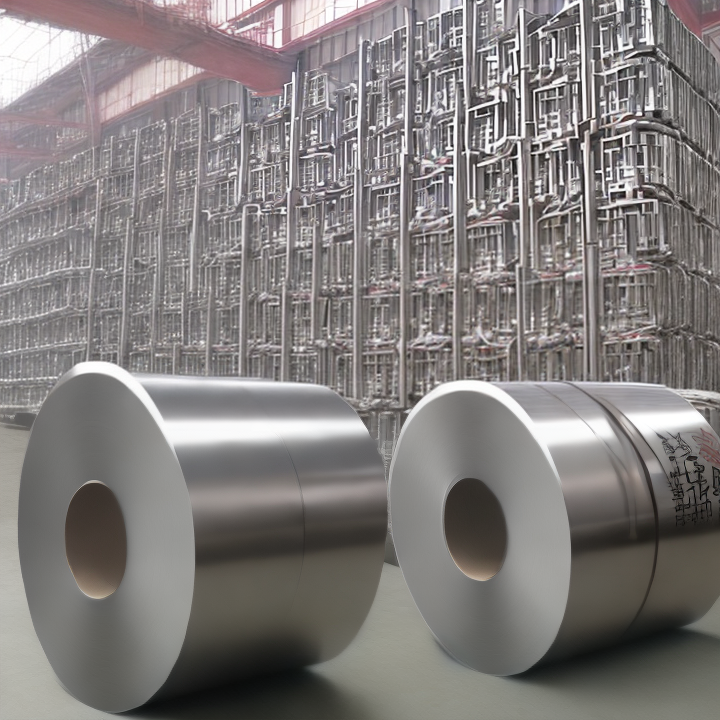

Aluminum coil China refers to aluminum coils made in China. Aluminum coils are made by rolling aluminum ingots through a series of rollers, which shape the aluminum into thin, flat sheets of the desired thickness. Aluminum coils are widely used in various industries due to their excellent properties such as corrosion resistance, light weight, high strength, and durability.

The following are the technical parameters of aluminum coil China:

1. Material: The primary material of aluminum coil China is 1xxx, 3xxx, 5xxx, 6xxx, and 8xxx series aluminum alloys.

2. Thickness: The thickness of aluminum coil China ranges from 0.2mm to 8mm.

3. Width: The width of aluminum coil China ranges from 100mm to 2600mm.

4. Coil ID: The coil ID of aluminum coil China can be 75mm, 150mm, 200mm, 300mm, 400mm, or 500mm.

5. Coil weight: The weight of aluminum coil China ranges from 100kg to 5000kg.

6. Surface treatment: Aluminum coil China can be coated with various coatings such as PVDF, PE, Epoxy, or Embossed.

7. Temper: The temper of aluminum coil China can be H14, H111, H112, H24, H32, H34, H36, or O.

8. Application: Aluminum coil China is widely used in various industries such as construction, transportation, aerospace, electronics, and packaging.

9. Standards: Aluminum coil China can be manufactured according to different standards such as ASTM, EN, GB, and JIS.

In conclusion, aluminum coil China is a versatile product with a wide range of technical parameters that can be customized to meet different needs and applications. Its various properties make it a popular choice for many industrial and commercial uses.

List Product features of “aluminum coil China”

Aluminum coil is a versatile material that is widely used in a variety of industries. When it comes to aluminum coil China, there are numerous features that make it a popular choice for many applications. Some of the key product features of aluminum coil China include:

1. Corrosion Resistance: Aluminum coil China is highly resistant to corrosion, which makes it ideal for use in harsh environments. This feature means that the material is less likely to rust or corrode over time, ensuring durability and lasting performance.

2. Lightweight: Aluminum coil China is known for its lightweight nature, making it easy to transport and handle. This lightweight characteristic makes it an ideal material for use in areas where weight is a critical factor.

3. Durability: Aluminum coil China offers excellent durability, making it resistant to wear and tear. This durability ensures that the material will last for a long time, even in harsh conditions.

4. Flexibility: Aluminum coil China is a flexible material that can be easily shaped and formed into various designs. This feature makes it ideal for use in applications where design flexibility is critical.

5. Easy to Clean: Aluminum coil China is easy to clean and maintain, making it a popular choice for applications where hygiene is essential.

6. Good Thermal Conductivity: Aluminum coil China has excellent thermal conductivity, which makes it ideal for use in heat transfer applications.

7. Recyclable: Aluminum coil China is a highly recyclable material, making it an environmentally friendly choice. This feature means that the material can be reused, helping to reduce waste and save energy.

In conclusion, the product features of aluminum coil China include corrosion resistance, lightweight, durability, flexibility, easy maintenance, good thermal conductivity, and recyclability. These features make aluminum coil China a versatile material with a wide range of applications.

List Application of “aluminum coil China”

1. Building and Construction Industry: Aluminum coils from China are popularly used in the building and construction industry for roofing, facades and cladding. The lightweight and corrosion-resistant properties make these coils ideal for use in modern architectural designs.

2. Transportation Industry: Aluminum coils are also commonly used in the transportation industry in the production of cars, trains, airplanes, and ships. The lightweight characteristic of the metal helps in significantly reducing the overall weight of the vehicle, thereby improving fuel efficiency.

3. Electrical and Electronic Industry: Aluminum coils play a significant role in the production of electrical and electronic devices and equipment. These coils are utilized for manufacturing electrical transformers, power capacitors, and electronic circuits due to their high electrical conductivity.

4. Packaging Industry: Aluminum coils are used in the packaging industry due to their unique barrier properties that protect contents from light, air, and moisture. The metal’s malleability makes it easy to manufacture aluminum foil for packaging purposes.

5. Industrial and Manufacturing Industry: Aluminum coils are utilized in many industrial and manufacturing processes, including aviation, aerospace, and defense. The metal’s strength, durability, and resistance to corrosion and heat make it ideal for use in these high-stress applications.

6. Heat Exchangers and HVAC Systems: Aluminum coils are an excellent material choice for heat exchangers and HVAC systems due to its unique thermal conductivity properties. This means that heat can be transferred quickly and efficiently, reducing energy consumption and costs.

7. Solar Panel Industry: Aluminum coils are commonly used in the solar panel industry due to their corrosion-resistant properties and high heat tolerance. They also provide an excellent reflectivity surface for concentrating solar power systems to increase the efficiency of the panels.

In conclusion, aluminum coils from China play a significant role in various industries due to their high strength, lightweight, durability, and corrosion-resistant properties. Their versatility and ability to cater to different industry needs make them a popular choice globally for many business applications.

List Various Types of “aluminum coil China”

Aluminum coil China is a commonly used product in a variety of industries. There are several types of aluminum coils, which are used based on the specific needs and requirements of different applications.

1. Aluminium sheet coil – This type of aluminum coil is made by forming an aluminum sheet into a coil shape. It is commonly used in the construction industry for roofing and cladding applications.

2. Embossed aluminium coil – This type of aluminum coil is produced with a pattern on the surface, providing a decorative effect. It is widely used in packaging, labels, and decoration purposes.

3. Color coated aluminum coil – This type of aluminum coil is coated with a layer of paint for aesthetic purposes. It is used for signage, traffic signs, and roofing materials.

4. Stucco aluminium coil – This type of aluminum coil has a textured surface, resembling stucco. It is commonly used in the automotive and HVAC industries.

5. Mirror finish aluminium coil – This type of aluminum coil has a reflective surface, similar to a mirror. It is used in decorative applications, such as lighting fixtures and furniture.

6. Anodized aluminum coil – This type of aluminum coil has a protective oxide layer, providing increased durability and corrosion resistance. It is used in electronics and aircraft industries.

7. Brushed aluminum coil – This type of aluminum coil has a brushed finish, providing a decorative effect. It is used in interior design, such as for kitchen appliances and elevator doors.

8. Perforated aluminum coil – This type of aluminum coil has small holes punched in the surface for ventilation and decoration purposes. It is used in building facades and decorative screens.

These are some of the common types of aluminum coil China available in the market. Each type has its specific applications and benefits, making it a necessary material in various industries.

List The Evolution history of “aluminum coil China”

The evolution of the Aluminum Coil industry in China can be traced back to the 1950s when the country started its industrialization process. During this time, the demand for Aluminum increased, and China became one of the top producers and consumers of aluminum in the world. However, the production of Aluminum Coil in China was limited since the country lacked the necessary technology and expertise to produce high-quality coils.

In the 1970s, China invested heavily in the Aluminum industry and started building Aluminum Coil production plants. The plants were equipped with advanced technology and machinery, which enabled them to produce large quantities of high-quality Aluminum Coils. This led to the growth of the Aluminum Coil industry in China.

During the 1990s, China became the largest producer and consumer of aluminum in the world. The Aluminum Coil industry continued to expand as the demand for Aluminum Coils increased. The industry also started to diversify its products, and manufacturers began to produce a wide range of Aluminum Coils to meet the growing demand.

In the early 2000s, the Chinese government introduced policies aimed at improving the quality of Aluminum Coils produced in China. This led to the improvement of production processes and the implementation of quality control measures in the industry. As a result, the Aluminum Coil industry in China became more efficient and started producing higher quality products.

Today, the Aluminum Coil industry in China is one of the largest in the world. China produces a wide range of high-quality Aluminum Coils, which are used in various industries, including construction, automotive, and aerospace. The industry has continued to evolve and innovate, and new technologies are being developed to improve production processes and enhance the quality of Aluminum Coils produced in China.

List The Process of “aluminum coil China”

The process of manufacturing aluminum coils in China involves several stages that begin with the extraction of bauxite, which is the primary source of aluminum. The bauxite is then refined into alumina using a Bayer process, which involves crushing and grinding the bauxite to form a powder. The alumina is then fused with cryolite, a natural mineral, to form a molten electrolyte solution that is used for the next stage.

In the next stage, the aluminum is produced from the molten electrolyte solution using the Hall-Heroult process, which involves passing an electric current through the solution to break down the aluminum oxide into aluminum and oxygen. The aluminum is then collected in large rectangular cells called pots, where it solidifies into ingots.

The ingots are then rolled to produce thin sheets of aluminum, which are used to create coils. The rolling process involves passing the sheets through a series of rollers that compress and stretch the metal to produce a thinner and more uniform sheet. This process is repeated several times until the desired thickness is achieved.

After the sheets have been rolled to the desired thickness, they are trimmed and cut into standard sizes for the production of coils. The coils are then packaged and shipped for use in a variety of applications, including construction, automobiles, and aerospace.

In summary, the process of manufacturing aluminum coils in China involves extracting bauxite, refining it into alumina, producing aluminum from the molten electrolyte solution, rolling the aluminum into thin sheets, cutting and trimming the sheets, and packaging them into coils for shipment. The process requires advanced technology and expertise, making China a major producer of aluminum coils for the global market.

How to use “aluminum coil China”

Aluminum coil, which is a type of metal material, is widely used in various industries such as construction, transportation, and packaging due to its lightweight, durability, and corrosion resistance. China is one of the leading manufacturing countries of aluminum coil and has a wide variety of suppliers that offer high-quality products at competitive prices.

To use aluminum coil in China, the following steps can be followed:

1. Determine the required specifications: Before purchasing aluminum coil in China, it is necessary to determine the required specifications such as the thickness, width, and length of the coil. This will ensure that the product meets the specific needs of the application.

2. Find a reliable supplier: There are numerous suppliers of aluminum coil in China, but it is important to find a reliable and trustworthy supplier that offers high-quality products and timely delivery.

3. Place an order: After identifying a suitable supplier, the next step is to place an order for the required quantity of aluminum coil. The supplier will provide a quote based on the specifications and quantity requested.

4. Arrange for delivery: Once the order is confirmed and payment has been made, the supplier will arrange for delivery of the aluminum coil to the designated location. It is important to ensure that the delivery is made on time and that the product arrives in good condition.

5. Use the aluminum coil: The aluminum coil can now be used in the intended application, such as in the construction of buildings, transport vehicles, or packaging materials.

In summary, using aluminum coil from China involves determining the required specifications, finding a reliable supplier, placing an order, arranging for delivery, and using the product in the intended application. It is important to choose a supplier that offers high-quality products and ensures timely delivery to ensure satisfaction and optimal performance of the product.

List Properties of “aluminum coil China”

Aluminum coil is a high-demand product commonly used in construction, automotive, and packaging industries. In China, aluminum coil manufacturers offer exceptional quality products that meet international standards. Aluminum coil China is gaining a massive following due to its numerous properties listed below.

1. Lightweight: Aluminum coil is a low-density metal with a specific gravity of 2.7. It is an excellent option for weight-sensitive applications, such as aircraft and automobile parts.

2. Corrosion resistance: Aluminum coil has a high resistance to corrosion since it forms a protective oxide layer when exposed to air. The oxide layer prevents further oxidization, making it ideal for harsh environments.

3. Durability: Aluminum coil China has excellent mechanical properties, including high strength and hardness, making it ideal for heavy-duty applications.

4. High electrical conductivity: Aluminum coil is an excellent conductor of electricity, making it a preferred material in electrical systems.

5. Low thermal expansion: Aluminum coil has a low coefficient of thermal expansion, meaning it minimally expands or contracts under temperature changes, making it ideal for use in delicate applications like high-speed racing cars.

6. Excellent formability: Aluminum coil can be formed into various shapes, including sheets, plates, coils, and foils, to fit different applications.

7. Recyclable: Aluminum coil is a sustainable material and 100% recyclable. Recycling aluminum requires only a fraction of the energy needed to produce it, making it an excellent choice for environmental advocates.

8. Versatility: Aluminum coil is widely applied in various industries such as aerospace, construction, transportation, packaging, and consumer goods.

In conclusion, Aluminum coil China is an excellent material choice for various applications, providing exceptional mechanical, electrical, and aesthetic properties. The high-quality manufacturing of aluminum coils meets international standards, providing a reliable and sustainable source of material.

List “aluminum coil China” FAQ

1. What is aluminum coil and what is it used for?

Aluminum coil is a thin, flat, and long piece of aluminum material that is rolled up into a coil shape. It is primarily used for manufacturing various products, such as building materials, electronic products, household appliances, and more.

2. What types of aluminum coils are available in China?

There are various types of aluminum coils available in China, including alloy aluminum coils, pre-painted aluminum coils, and embossed aluminum coils.

3. What are the advantages of using aluminum coil in manufacturing?

Aluminum coil offers many advantages, such as low weight, good corrosion resistance, high thermal conductivity, and more. It is also readily available and can be easily molded into various shapes and sizes.

4. What is the production process for aluminum coil?

The production process for aluminum coil involves melting and casting the aluminum into ingots, which are then rolled and flattened into sheets. These sheets are then further processed and rolled up into coils.

5. Which industries use aluminum coil?

Aluminum coil is widely used in many industries, including construction, transportation, electronics, and packaging. It is used for products such as roofing systems, car parts, electronic components, and more.

6. What is the minimum order quantity for aluminum coil in China?

The minimum order quantity for aluminum coil varies by manufacturer and product specifications. However, many manufacturers typically require a minimum order quantity of 5 metric tons.

7. What is the lead time for aluminum coil production in China?

The lead time for aluminum coil production in China varies by manufacturer and product specifications. However, it typically takes around 4 to 6 weeks from the time the order is placed to the time the product is ready for shipment.

8. Are there any quality standards for aluminum coil in China?

Yes, there are several quality standards for aluminum coil in China, including the GB/T 3880-2018 and ASTM B209 standards.

9. What is the packaging method for aluminum coil in China?

Aluminum coil is typically packaged in wooden pallets and strapped with steel strips to ensure safe delivery. The coils are also covered with protective materials, such as plastic or paper, to prevent damage during transit.

10. Can aluminum coil be customized in China?

Yes, many manufacturers in China offer custom-designed aluminum coils to meet specific requirements. This includes customization of alloy composition, thickness, width, and other specifications.