The world of pillow production has seen significant advancements over the years, with the introduction of various filling materials ranging from polyester-derived to natural fibers of different origins. This diversity in the market, driven by evolving consumer preferences, has necessitated the need for advanced machinery to cater to these demands. Enter the pillow filling machine, a marvel of modern engineering that has revolutionized the way pillows are produced.

China, known for its manufacturing prowess, has emerged as a leading player in the production of these machines. With a rich history of innovation and a commitment to quality, China has positioned itself as a go-to destination for businesses looking to source high-quality pillow filling machines at competitive prices.

Types and Applications of Pillow Filling Machines

Pillow filling machines have evolved to accommodate a wide range of materials, ensuring that manufacturers can produce pillows that cater to every preference. From the plush softness of polyester fibers to the natural comfort of wool or kapok, these machines have been designed to handle it all.

- Polyester Fibers: The most common filling, known for its durability and cost-effectiveness. Machines designed for polyester often come with settings that allow for varying degrees of fluffiness.

- Cluster Fibers: These are small balls of polyester fibers that give pillows a soft and luxurious feel. They require specialized machines that can handle their unique structure.

- Microfibers: A finer version of polyester, microfibers offer a soft, down-like feel without the allergens. Machines handling microfibers are equipped with precision settings to ensure even distribution.

- Natural Fibers: This category includes materials like wool, kapok, and even feathers. They require machines that can handle their unique properties without compromising on the natural benefits they offer.

The application of these machines isn’t limited to just pillows. Many are versatile enough to be used for cushions, soft toys, and other stuffed items, making them invaluable assets for manufacturers in the home textiles industry.

SourcifyChina: Your Trusted Partner in China

Established in 2007, SourcifyChina has carved a niche for itself by offering expert product sourcing services tailored for small and medium-sized foreign trade enterprises. With a vast network of experienced Chinese factories and professionals, they have facilitated connections for over 3,000 customers, with 500 of them maintaining a successful relationship for over a decade.

What sets SourcifyChina apart is their commitment to ensuring that their clients get the best value for their money. With a service fee as low as 3%, they offer a cost-effective solution for businesses looking to source products from China. Their extensive network and experience in the field also mean that they can provide insights that might be hard to come by otherwise, such as the creditworthiness of Chinese companies.

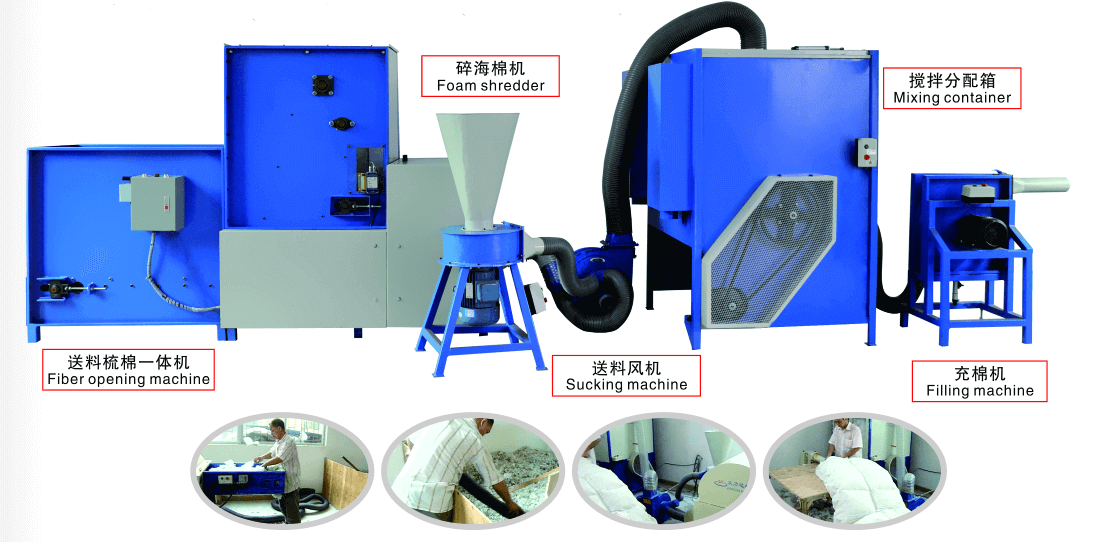

The Production Process of Pillow Filling Machines

The journey from raw materials to a finished, fluffy pillow is a testament to the marvel of modern manufacturing. The production process of pillow filling machines is intricate, ensuring that every pillow produced meets the highest standards of quality and comfort.

- Material Preparation: Before the actual filling process begins, the chosen material, be it polyester, microfiber, or natural fibers, is prepared. This involves cleaning, sorting, and sometimes blending different materials to achieve the desired consistency and feel.

- Feeding the Material: Advanced machines come equipped with automatic feeding systems. These systems ensure a consistent flow of material into the machine, eliminating the need for manual intervention and ensuring uniformity in the finished product.

- Filling Process: This is the heart of the machine. Depending on the type of material and the desired end product, the filling process can vary. For instance, machines designed for cluster fibers have mechanisms to ensure that the clusters remain intact and are evenly distributed.

- Quality Control: Once the pillows are filled, they undergo rigorous quality checks. This ensures that every pillow meets the set standards in terms of weight, consistency, and feel.

- Packaging: The final step involves packaging the pillows for shipment. Advanced machines often come with integrated packaging systems, ensuring that the pillows are packed securely and are ready for shipment.

Step-by-Step Guide to Using a Pillow Filling Machine

Operating a pillow filling machine requires a blend of technical know-how and attention to detail. Here’s a step-by-step guide to ensure smooth operation:

- Safety First: Before starting the machine, ensure that all safety protocols are in place. This includes wearing protective gear and ensuring that the machine is in good working condition.

- Setting the Machine: Depending on the type of material and the desired output, set the machine parameters. This includes setting the feed rate, filling density, and other relevant parameters.

- Feeding the Material: Load the material into the feeding system. Ensure that there are no blockages or knots in the material.

- Monitor the Process: As the machine operates, keep a close eye on the filling process. Ensure that the pillows are being filled evenly and that there are no malfunctions.

- Routine Maintenance: Regularly clean and maintain the machine to ensure longevity and consistent performance. This includes cleaning the feed system, checking for wear and tear, and lubricating moving parts.

Questions Every International Buyer Should Ask Their Chinese Supplier

When venturing into the world of international trade, especially with a powerhouse like China, it’s crucial to be well-informed. Here are some essential questions every international buyer should consider when engaging with a Chinese supplier:

- Can you provide references or testimonials from previous clients? This helps in gauging the supplier’s credibility and track record.

- What are your payment terms and conditions? Understanding the payment structure can prevent potential financial disputes in the future.

- How do you ensure the quality of the products? This gives insight into their quality control measures and standards.

- What is the lead time for production and delivery? This helps in planning and managing inventory efficiently.

- Are there any certifications or standards that your products adhere to? Especially important for products that have strict international standards.

- How do you handle discrepancies or issues with the final product? Knowing the supplier’s approach to problem-solving can be invaluable.

- Can you provide samples before a bulk order? This allows for a tangible quality check before committing to a large order.

- What are the shipping and logistics arrangements? Understanding the logistics can help in planning the product’s journey from the factory to its final destination.

- Are there any additional costs involved, such as taxes or customs duties? Hidden costs can affect the product’s final price, so it’s essential to be aware of them.

- How do you stay updated with industry trends and technological advancements? This gives an idea of the supplier’s commitment to innovation and staying relevant in the market.

FAQ Tips: Understanding Pillow Filling Machines

What types of materials can a pillow filling machine handle? Answer: Pillow filling machines are versatile and can handle a range of materials, including polyester fibers, cluster fibers, microfibers, and natural fibers like wool or kapok.

How energy-efficient are these machines? Answer: Modern pillow filling machines are designed with energy efficiency in mind. However, the exact efficiency can vary based on the model and manufacturer. It’s always advisable to check the machine’s specifications or consult the supplier.

What is the average production capacity of a pillow filling machine? Answer: The production capacity can vary widely based on the machine’s design and settings. Some advanced machines can produce between 1,000 to 4,000 pillows per shift.

How much manual intervention is required during the machine’s operation? Answer: While many modern machines offer automated features, some processes might require manual intervention. The degree of manual work depends on the machine’s design and the desired output.

How long can I expect a pillow filling machine to last? Answer: With proper maintenance and care, a pillow filling machine can last for several years. The lifespan also depends on the frequency of use and the machine’s build quality.

Can these machines handle custom pillow sizes or shapes? Answer: Yes, many pillow filling machines come with settings that allow for customization in terms of size and shape. However, it’s essential to discuss specific requirements with the supplier.

What safety features are integrated into these machines? Answer: Safety is paramount. Most machines come equipped with emergency stop buttons, overload protection, and other safety features to ensure the operator’s well-being.

Do suppliers provide training for operating these machines? Answer: Yes, reputable suppliers often offer comprehensive training programs to ensure that users can operate the machine efficiently and safely.

How do I handle maintenance and potential repairs? Answer: Regular maintenance is crucial for the machine’s optimal performance. Suppliers often provide maintenance guidelines. For repairs, it’s advisable to consult the supplier or a professional.

Are there any warranties or guarantees provided with the machine? Answer: Most suppliers offer warranties or guarantees for their machines. The duration and terms can vary, so it’s essential to discuss this with the supplier before making a purchase.