China’s Top Shot Blast Machine Supplier: Custom Process & Competitive Price

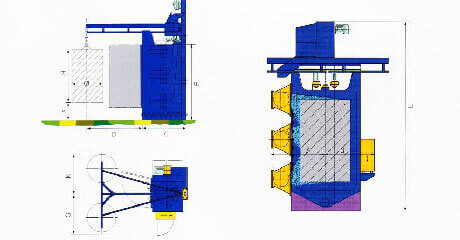

Overhead Rail Shot Blast Machine

Description: The Overhead Rail Shot Blast Machine stands out as one of the most versatile machine types, meticulously designed for the economical and efficient surface treatment of a myriad of workpieces.

Applications:

- Cleaning forged parts, pumps, and fittings.

- Decorative blasting for nonferrous metal surfaces.

- Deburring for die casting, stamped parts, and more.

Key Features:

- Capability to load a new batch of workpieces while the machine processes another.

- Quick turnaround with straightforward assembly.

- Equipped with highly efficient blast wheels.

- Incorporates automatic PLC control.

- Available in multiple sizes and variations.

Technical Specifications:

- Machine Type: ORB-10/12, ORB-12/16, ORB-12/20

- Number of Blast Wheels: 2 (for ORB-10/12 and ORB-12/16), 3 (for ORB-12/20)

- Wheel Capacity: 2×7.5 kW, 2×11 kW, 3×11 kW respectively

- Max Diameter of Workpiece Batch: 1000 mm, 1200 mm, 1200 mm respectively

- Max Height of Workpiece: 1200 mm, 1600 mm, 2000 mm respectively

- Max Weight of Workpiece: 250 kg, 350 kg, 500 kg respectively

- Abrasive Initial Feeding: 450 kg, 600 kg, 900 kg respectively

- Electronic Connection Power: 22 kW, 29 kW, 42 kW respectively

Roller Conveyor Shot Blast Machine

Description: The Roller Conveyor Shot Blast Machine is primarily crafted for the treatment of metal plates or profiles, catering especially to the steel construction or steel preparation sectors.

Understanding Shot Blast Machines

Shot blasting is a method used to clean, strengthen, or polish metals. This process is essential in the metallurgical industry, especially in applications where the final product’s surface finish is critical. The Shot Blast Machine plays a pivotal role in this process, ensuring that metals are adequately prepared for their intended use.

Definition and Working Principle

A Shot Blast Machine propels abrasive material (often referred to as ‘shots’ or ‘grit’) under high pressure onto the surface of a metal. This action helps in removing surface contaminants, preparing the metal for subsequent processes like painting or coating. The machine consists of a blasting wheel that throws the abrasive material at the metal surface. As the abrasive material strikes the surface, it effectively cleans it by knocking off rust, scale, and other contaminants.

Key Components and Their Functions

- Blasting Wheel: This is the heart of the machine. It propels the abrasive material at high speeds towards the metal surface. The efficiency of the blasting process largely depends on the wheel’s design and speed.

- Work Chamber: This is where the actual blasting takes place. It is designed to contain the abrasive materials and the parts being blasted.

- Abrasive Recovery System: After the blasting process, not all abrasive materials stick to the metal surface. The recovery system collects, cleans, and recirculates the unused abrasive material, ensuring minimal wastage.

- Dust Collector: This component ensures that the work environment remains clean by collecting and filtering out the dust produced during the blasting process.

- Control System: Modern Shot Blast Machines come with advanced control systems that allow operators to adjust various parameters like blasting pressure, abrasive material type, and more.

China, with its advanced manufacturing capabilities, has become a leading supplier of Shot Blast Machines. Companies like Lead Machinery offer custom CNC machining services, ensuring that the machines are tailored to specific industry needs. Moreover, with the support of sourcing experts like SourcifyChina, international buyers can easily navigate the vast pool of Chinese suppliers, ensuring they get the best quality machines at competitive prices.

Types and Applications of Shot Blast Machines

Shot Blast Machines come in various designs and configurations, each tailored to meet specific industry needs. Understanding these types and their applications can help businesses make informed decisions when investing in such machinery.

Different Models and Their Specific Uses

- Tumble Blast Machines: These are rubber belt conveyor systems where parts are loaded into a tumbling action, exposing all surfaces to the blasting stream. They are ideal for batch-type operations and are commonly used for descaling, deflashing, and deburring.

- Table Blast Machines: In these machines, parts are placed on a rotating table, and the blast wheel positioned above the table propels the abrasive material. They are perfect for cleaning large, flat surfaces.

- Spinner Hanger Machines: These are designed for parts that cannot be tumbled due to their shape or fragility. Parts are hung and then passed through the blast stream for cleaning.

- Pipe Blasting Machines: Specifically designed for cleaning the exterior of pipes, these machines ensure uniform cleaning and finishing.

- Portable Blasting Machines: These are mobile units used for cleaning structures like bridges, ships, and large equipment. They are versatile and can be moved to different sites as needed.

Industries that Benefit the Most

- Automotive: For cleaning and preparing car parts before painting or coating.

- Aerospace: Ensuring aircraft parts are free from contaminants and have a smooth finish.

- Construction: For cleaning and preparing structural steel, beams, and other materials.

- Shipbuilding: Removing rust, scale, and old paint from ship surfaces before repainting.

- Railways: Maintenance and cleaning of train components.

- Foundries: Cleaning and preparing molds and castings.

China’s prominence in the manufacturing sector has led to the country becoming a hub for high-quality Shot Blast Machines. Companies like Lead Machinery, with their advanced equipment and expertise, offer a wide range of materials and finishes, ensuring the highest standards. Furthermore, with SourcifyChina’s expert product sourcing services, international businesses can find reliable and experienced Chinese factories, ensuring stable quality and competitive prices.

The Production Process of Shot Blast Machines

Manufacturing a Shot Blast Machine is a meticulous process that requires precision, expertise, and a deep understanding of the machine’s working principles. The production process not only ensures the machine’s efficiency but also its longevity and reliability.

Raw Materials and Their Sourcing

- Steel and Iron: These are the primary materials used in the construction of the machine’s body and internal components. Their strength and durability are crucial for the machine’s overall performance.

- Rubber and Plastics: Used in the making of conveyor belts, seals, and protective linings to ensure the smooth movement of parts and prevent abrasive material leakage.

- Electrical Components: These are essential for the machine’s control system, ensuring that the machine operates safely and efficiently.

China, with its vast resources and advanced manufacturing capabilities, ensures that these raw materials are of the highest quality. Companies like Lead Machinery source their materials meticulously, ensuring they meet international standards.

Manufacturing Steps and Quality Control

- Design and Blueprint Creation: Engineers create detailed blueprints of the machine, ensuring every component is accurately represented.

- Material Cutting and Shaping: Using advanced CNC machines, the raw materials are cut and shaped according to the design specifications.

- Assembly: Components are assembled in a systematic manner. This includes mounting the blasting wheel, setting up the conveyor system, and integrating the control system.

- Testing: Once assembled, the machine undergoes rigorous testing. This ensures that it operates efficiently and safely.

- Finishing: The machine’s surface is treated to prevent rust and corrosion. This can include processes like anodizing, polishing, sandblasting, and powder coating.

- Quality Control: Every machine is inspected for any defects or issues. This ensures that the final product meets the company’s quality standards and the expectations of the clients.

China’s commitment to quality and innovation has made it a preferred destination for businesses looking for reliable Shot Blast Machines. With companies like Lead Machinery offering customized solutions and SourcifyChina aiding in the sourcing process, international buyers are assured of getting the best machines at competitive prices.

In the subsequent section, we will provide a comprehensive guide on using Shot Blast Machines, ensuring operators can maximize the machine’s potential while ensuring safety.

Using Shot Blast Machines: A Step-by-Step Guide

Operating a Shot Blast Machine requires a combination of technical knowledge and safety awareness. This section provides a comprehensive guide to ensure that operators can achieve optimal results while maintaining a safe working environment.

Installation and Setup

- Site Preparation: Choose a location with adequate space for the machine, ensuring there’s room for movement and maintenance activities. The floor should be level and capable of bearing the machine’s weight.

- Electrical Connections: Connect the machine to a power source, ensuring that the voltage and frequency match the machine’s specifications. It’s advisable to have a dedicated power line to prevent fluctuations.

- Air Supply: Ensure a steady supply of compressed air if the machine requires it. Check for any leaks or blockages in the air lines.

- Abrasive Material Loading: Load the chosen abrasive material into the machine’s designated compartment. Ensure it’s free from contaminants.

Operational Guidelines and Safety Measures

- Safety First: Operators should wear protective gear, including safety glasses, ear protection, and dust masks. Ensure that the work area is well-ventilated.

- Machine Warm-Up: Before starting a blasting session, run the machine for a few minutes to ensure all components are working correctly.

- Setting Parameters: Adjust the machine’s settings, such as blasting pressure and abrasive material flow rate, based on the requirements of the task.

- Continuous Monitoring: While the machine is in operation, continuously monitor its performance. Listen for any unusual noises and check for any signs of wear or malfunction.

- Shutdown Procedure: Once the blasting session is complete, turn off the machine following the manufacturer’s guidelines. Clean the machine and remove any residual abrasive material.

- Routine Maintenance: Regularly inspect the machine for signs of wear or damage. Replace worn-out parts and ensure that all components are well-lubricated.

China’s Shot Blast Machine manufacturers, like Lead Machinery, often provide detailed user manuals and training sessions, ensuring that operators are well-equipped to handle the machinery. Additionally, with the support of companies like SourcifyChina, international buyers can access post-sales services and technical support, ensuring the machine’s longevity and optimal performance.

Price and Cost Analysis

Understanding the cost structure of Shot Blast Machines is crucial for businesses aiming to make informed purchasing decisions. While the initial price is a significant factor, it’s essential to consider the total cost of ownership, which includes maintenance, operational costs, and potential savings from increased efficiency.

Factors Affecting the Cost

- Machine Size and Capacity: Larger machines with higher capacities generally come at a higher price point due to the increased material and manufacturing complexity.

- Customization: Bespoke features or modifications tailored to specific business needs can influence the final price.

- Material Quality: High-grade materials, known for their durability and performance, can increase the machine’s cost.

- Technological Features: Advanced features, such as automated control systems, sensors, and IoT capabilities, can add to the machine’s price.

- Brand and Reputation: Established brands with a track record of quality and reliability might command a premium.

- Shipping and Import Duties: Depending on the destination, shipping costs and import duties can significantly impact the final cost to the buyer.

Tips to Get the Best Price from Suppliers

- Bulk Purchasing: Ordering multiple units or bundling with other products can lead to volume discounts.

- Negotiation: Engage in open discussions with suppliers. Often, there’s room for negotiation, especially for long-term partnerships.

- Research and Compare: Before settling on a supplier, research multiple options, compare their offerings, and read reviews or testimonials.

- Leverage Expertise: Utilize sourcing experts like SourcifyChina to navigate the vast supplier landscape, ensuring you get the best deal without compromising on quality.

- Understand Total Cost of Ownership: Look beyond the initial price. Consider factors like maintenance costs, operational efficiency, and potential savings from increased productivity.

- Seek Transparent Quotations: Ensure that the supplier provides a detailed quotation, breaking down all costs, including potential add-ons or post-sales services.

The Value Proposition of Chinese Suppliers

Chinese manufacturers, like Lead Machinery, offer competitive prices without compromising on quality. Their advanced manufacturing capabilities, combined with efficient production methods, ensure that businesses receive value for their investment. Moreover, with the support of sourcing specialists like SourcifyChina, international buyers can navigate the complexities of procurement, ensuring transparency and reliability.

Questions International Buyers Should Ask Chinese Suppliers

Engaging with Chinese suppliers requires a strategic approach, ensuring that the partnership aligns with business objectives and quality standards. Here are some pivotal questions that international buyers should consider when interacting with Chinese manufacturers:

- Company Verification:

- How long has your company been in the Shot Blast Machine manufacturing business?

- Can you provide any certifications or licenses that validate your manufacturing capabilities?

- Product Quality and Standards:

- What quality control measures do you have in place during the manufacturing process?

- Do your products meet international standards, and can you provide relevant certifications?

- Customization and Flexibility:

- What customization options do you offer for Shot Blast Machines?

- How flexible are you with design modifications or specific requirements?

- Production Capacity and Lead Time:

- What is your production capacity, and how long is the typical lead time for orders?

- Can you handle bulk orders, and how does it impact the delivery timeline?

- Post-Sales Services and Warranty:

- What kind of after-sales support do you provide?

- Do you offer a warranty on your Shot Blast Machines, and what does it cover?

- Client References and Testimonials:

- Can you provide references or testimonials from previous international clients?

- Have you supplied to businesses in our region or industry before?

- Pricing and Payment Terms:

- How is the pricing determined, and are there any additional costs we should be aware of?

- What are your payment terms, and do you offer any discounts for long-term partnerships or bulk orders?

- Shipping and Logistics:

- Do you handle shipping and logistics, or is it the buyer’s responsibility?

- How do you ensure the safe transit of machinery, especially for international shipments?

- Intellectual Property Protection:

- How do you ensure the protection of any designs, blueprints, or intellectual property shared during the collaboration?

- Continuous Collaboration:

- How do you handle feedback and continuous improvement in the manufacturing process?

- Are there opportunities for joint ventures or deeper collaboration in the future?

Engaging with suppliers like Lead Machinery, known for their reputation and quality, can simplify the process. However, leveraging the expertise of sourcing platforms like SourcifyChina can further streamline the procurement process, ensuring that international buyers connect with reliable and experienced Chinese suppliers.

Related products

Industrial Machinery

China’s Top Line Boring Machine Supplier: Custom Services & Factory Prices

Industrial Machinery

Industrial Machinery

Industrial Machinery

China’s Leading Slotting Machine Supplier: Custom Services & Factory Prices

Useful Links & Infomation

©2023. sourcifychina.com All Rights Reserved.

-

- Home

- Retail Cheap Shop

- Wholesale Featured Pro

- Industries

- List

- Our China Suppliers list

- Auto Parts Suppliers

- Packaging Solution

- Stainless Steel Suppliers

- Steel Pipe Suppliers

- Solar Inverter China

- cable manufacturing

- cnc machining China

- Apparel and Accessories

- fabric manufacturing

- Machinery

- pump China

- Screw

- wigs custom

- valves manufacturing

- hair system custom

- heated gloves wholesale

- indoor lighting fixtures

- solor panel wholesale

- snow boots factory

- Products

- Manufacturing

- Guide

- Apparel / Fashion Accessories

- CNC Tools Valve Pump Parts

- Machinery China Equiment Sourcing Guide

- aac block manufacturers

- acrylic cutting machine

- automatic packing machine

- Auxiliary Equipment

- blister packing machine

- bricks manufacturing

- clay brick making machine

- feed pellet machine

- fly ash bricks machine sourcing guide

- paper bag making machine

- pellet machine

- plastic crusher machine

- pouchpacking machine

- stamping machine

- wood pellet machine

- Outdoor Sports

- Others Sourcing Guide

- FAQ

- About

- Contact

- Login

- Newsletter

- [email protected] whatsapp 8615951276160

- 供应商

Login

- →

- WeChat: 8615951276160