A Beginner’s Guide to cnc laser cutting machine manufacturers

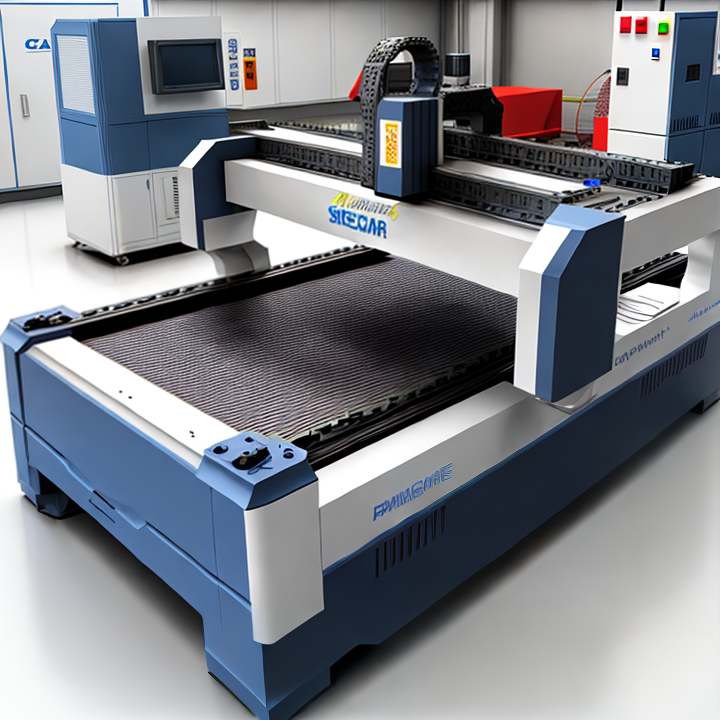

CNC laser cutting machines are computer-controlled devices that use a high-powered laser beam to cut and engrave various materials with precision and accuracy. These machines have become increasingly popular in various industries, including automotive, aerospace, electronics, and manufacturing, due to their efficiency and versatility. If you are new to CNC laser cutting machines, here is a beginner’s guide to help you understand the basics and find the right manufacturer.

1. Types of CNC laser cutting machines: There are mainly two types of CNC laser cutting machines – CO2 lasers and fiber lasers. CO2 lasers are suitable for cutting and engraving non-metallic materials such as wood, acrylic, and plastic, while fiber lasers are ideal for cutting metals like stainless steel, aluminum, and brass.

2. Features to consider: When choosing a CNC laser cutting machine, consider factors such as cutting speed, accuracy, power output, and ease of use. A higher power output will allow you to cut through thicker materials, while a faster cutting speed will increase productivity. Additionally, look for machines with user-friendly software and control systems for easy operation.

3. Research manufacturers: Before purchasing a CNC laser cutting machine, research various manufacturers to find one that offers high-quality machines at a competitive price. Look for manufacturers with a strong reputation in the industry, positive customer reviews, and comprehensive after-sales support.

4. Compare prices and warranties: Prices for CNC laser cutting machines can vary significantly depending on the type, features, and manufacturer. Compare prices from different manufacturers and consider the warranty offered on the machine. A longer warranty period indicates the manufacturer’s confidence in the quality and durability of their product.

5. Attend trade shows and demonstrations: To get a better understanding of CNC laser cutting machines and their capabilities, attend trade shows and demonstrations where manufacturers showcase their products. This will give you an opportunity to ask questions, see the machines in action, and make an informed decision.

In conclusion, finding the right CNC laser cutting machine manufacturer involves understanding the types of machines available, considering the features you need, researching manufacturers, comparing prices and warranties, and attending trade shows and demonstrations. By following these steps, you can find a reliable and high-quality CNC laser cutting machine that meets your needs and budget.

How to Select a Reliable cnc laser cutting machine manufacturers

Selecting a reliable CNC laser cutting machine manufacturer is crucial for ensuring the quality, efficiency, and longevity of your equipment. Here are some key factors to consider when choosing a manufacturer:

1. Reputation: Research the reputation of the manufacturer in the industry. Look for reviews, testimonials, and case studies from their existing customers. A well-established and reputable company will have a proven track record of delivering high-quality machines and excellent customer service.

2. Experience: Choose a manufacturer with extensive experience in the CNC laser cutting machine industry. This ensures that they have the necessary knowledge and expertise to design and produce machines that meet your specific needs and requirements.

3. Technical Support: A reliable manufacturer should offer comprehensive technical support, including installation, training, and after-sales service. Make sure the company has a dedicated team of engineers and technicians who can provide prompt and efficient assistance when needed.

4. Quality Assurance: Check if the manufacturer has a quality management system in place, such as ISO certification. This demonstrates their commitment to producing high-quality machines and maintaining consistent standards throughout the production process.

5. Customization Options: A good manufacturer should be able to offer customization options to meet your specific requirements. This may include different power levels, cutting speeds, and software compatibility.

6. Warranty and After-sales Service: A reliable manufacturer should provide a warranty for their machines, as well as after-sales service and support. This ensures that you have peace of mind knowing that any issues with your machine will be promptly addressed.

7. Price: While the price should not be the sole determining factor, it is essential to consider the cost of the machine and compare it with other manufacturers. Look for a manufacturer that offers competitive pricing without compromising on quality and performance.

8. Local Presence: If possible, choose a manufacturer with a local presence in your region. This ensures that you can easily access their technical support, spare parts, and maintenance services when needed.

In summary, selecting a reliable CNC laser cutting machine manufacturer involves researching their reputation, experience, technical support, quality assurance, customization options, warranty, price, and local presence. By considering these factors, you can make an informed decision and invest in a high-quality machine that meets your needs and requirements.

Comparing cnc laser cutting machine manufacturers and Suppliers: Which is Better?

When comparing CNC laser cutting machine manufacturers and suppliers, it is essential to consider various factors such as product quality, customer support, pricing, and company reputation. Two well-known CNC laser cutting machine manufacturers and suppliers are Trumpf and Amada. Both companies have a strong presence in the market and offer a wide range of products and services. However, there are some differences between the two that may influence your decision.

1. Product Quality: Both Trumpf and Amada are known for their high-quality CNC laser cutting machines. However, Trumpf is often considered to have a slight edge in terms of precision and accuracy. Their machines are known for their durability and reliability, which can result in lower maintenance costs and longer machine life. On the other hand, Amada machines are also highly reliable and offer excellent cutting performance.

2. Customer Support: Both companies offer extensive customer support, including training, technical assistance, and maintenance services. However, Trumpf is known for its more comprehensive and responsive customer support, which can be crucial in minimizing downtime and ensuring the smooth operation of your CNC laser cutting machine.

3. Pricing: In general, Trumpf machines tend to be more expensive than Amada machines. However, this higher price point may be justified by the superior quality and performance of Trumpf machines. It is essential to consider the total cost of ownership, including maintenance and support costs, when comparing prices between the two companies.

4. Company Reputation: Both Trumpf and Amada have strong reputations in the CNC laser cutting machine industry. Trumpf is a German company with a long history of innovation and excellence in engineering, while Amada is a Japanese company known for its commitment to quality and customer satisfaction. Both companies have a global presence and are well-regarded by customers and industry experts alike.

In conclusion, both Trumpf and Amada are excellent choices for CNC laser cutting machine manufacturers and suppliers. While Trumpf may have a slight advantage in terms of product quality and customer support, Amada offers competitive pricing and a strong reputation for quality and reliability. Ultimately, the best choice will depend on your specific needs, budget, and preferences. It is essential to thoroughly research and compare the offerings of both companies before making a decision.

The Manufacturing Process of cnc laser cutting machine manufacturers

CNC laser cutting machine manufacturers follow a systematic manufacturing process to produce high-quality, precise, and efficient cutting machines. The process involves several stages, including design, material selection, fabrication, assembly, testing, and quality control.

1. Design: The first step in the manufacturing process is designing the CNC laser cutting machine. Engineers and designers use computer-aided design (CAD) software to create detailed 3D models of the machine components, including the frame, laser head, control system, and other parts. They also determine the specifications, such as cutting speed, accuracy, and power requirements.

2. Material selection: Manufacturers choose high-quality materials for the machine’s components to ensure durability, stability, and precision. Common materials include stainless steel, aluminum, and other metals for the frame and laser head, as well as electronic components for the control system.

3. Fabrication: The fabrication process involves cutting, shaping, and forming the various components of the CNC laser cutting machine. This can include laser cutting, bending, and welding of metal parts, as well as machining processes such as milling, drilling, and turning for more complex components.

4. Assembly: Once all the components are fabricated, they are assembled to create the final CNC laser cutting machine. This involves attaching the laser head to the frame, installing the control system, and connecting all the necessary wiring and cables. The assembly process requires skilled technicians to ensure that all components are aligned and functioning correctly.

5. Testing: After assembly, the CNC laser cutting machine undergoes rigorous testing to ensure it meets the required specifications and performs accurately and efficiently. This can include testing the machine’s cutting speed, accuracy, and power output, as well as checking for any defects or malfunctions.

6. Quality control: Throughout the manufacturing process, quality control measures are in place to ensure that the CNC laser cutting machine meets the highest standards of quality and performance. This can include regular inspections of materials, components, and the final product, as well as adherence to industry standards and certifications.

In conclusion, CNC laser cutting machine manufacturers follow a meticulous process to design, fabricate, assemble, and test their machines, ensuring they deliver high-quality, precise, and efficient cutting solutions to various industries.

Custom Manufacturing Options for cnc laser cutting machine manufacturers

CNC laser cutting machine manufacturers offer a wide range of custom manufacturing options to cater to the diverse needs of their clients. These options allow businesses to optimize their production processes and achieve high-quality results. Here are some of the most popular custom manufacturing options available:

1. Material Selection: Manufacturers can customize the type of material used for laser cutting, such as stainless steel, aluminum, brass, copper, or various plastics. This ensures that the final product meets the specific requirements of the client’s industry and application.

2. Cutting Thickness: Depending on the material and the machine’s capabilities, manufacturers can offer different cutting thicknesses to suit the client’s needs. This allows for precise and accurate cuts, regardless of the material’s thickness.

3. Cutting Speed: Customizable cutting speeds enable manufacturers to optimize the production process, ensuring faster turnaround times and increased efficiency.

4. Laser Power: Manufacturers can offer machines with varying laser power levels, allowing clients to choose the most suitable option for their specific cutting requirements. Higher laser power levels enable faster cutting speeds and increased cutting thicknesses.

5. Software Integration: CNC laser cutting machines can be integrated with various software programs, allowing for seamless communication between the machine and the client’s design software. This ensures accurate and efficient production processes.

6. Automation Options: Manufacturers can provide automation options such as automatic material loading and unloading systems, which can significantly increase production efficiency and reduce labor costs.

7. Customized Worktable: Depending on the client’s requirements, manufacturers can offer customized worktables with different sizes and configurations, ensuring optimal workspace utilization.

8. Safety Features: Manufacturers can incorporate various safety features into their CNC laser cutting machines, such as protective enclosures, safety interlocks, and emergency stop buttons, to ensure a safe working environment for operators.

9. Training and Support: Customized training and support services can be provided by manufacturers to ensure that clients can effectively operate and maintain their CNC laser cutting machines.

10. Warranty and After-sales Service: Manufacturers can offer different warranty periods and after-sales service options, ensuring that clients receive the necessary support and assistance throughout the machine’s lifecycle.

In conclusion, CNC laser cutting machine manufacturers offer a wide range of custom manufacturing options to cater to the diverse needs of their clients. By choosing the right combination of options, businesses can optimize their production processes and achieve high-quality results.

Quality Control in cnc laser cutting machine manufacturers

Quality control is a crucial aspect for CNC laser cutting machine manufacturers as it ensures that the machines produced are reliable, efficient, and meet the required industry standards. It involves a series of processes and checks to guarantee that the final product is free from defects and performs optimally. Here are some key quality control measures implemented by CNC laser cutting machine manufacturers:

1. Raw Material Inspection: The quality control process begins with the inspection of raw materials used in the production of CNC laser cutting machines. Manufacturers source high-quality materials and components to ensure the durability and efficiency of the machines. These materials are thoroughly inspected and tested before being used in the production process.

2. Design and Engineering: Quality control is also maintained during the design and engineering phase. Engineers and designers work together to develop innovative and efficient machine designs that meet the specific requirements of the customers. They use advanced software and simulation tools to test and optimize the machine designs before moving on to the production stage.

3. Production Process Monitoring: During the production process, manufacturers implement strict quality control measures to ensure that each machine is built to the highest standards. This involves monitoring and controlling various production parameters, such as cutting speed, accuracy, and repeatability. In addition, manufacturers use advanced manufacturing techniques, such as lean manufacturing and Six Sigma, to minimize errors and improve overall production efficiency.

4. In-process Inspection: Quality control inspectors conduct in-process inspections at various stages of the production process to identify and rectify any defects or deviations from the set standards. This helps in maintaining the quality of the machines and ensures that they meet the required specifications.

5. Final Testing and Inspection: Once the CNC laser cutting machines are assembled, they undergo rigorous testing and inspection to ensure their performance, accuracy, and safety. This includes functional testing, dimensional inspection, and safety checks. Only machines that pass these tests are approved for shipment to customers.

6. After-sales Support and Training: Quality control does not end with the delivery of the machines. Manufacturers provide after-sales support and training to customers to ensure the proper operation and maintenance of the machines. This helps in maintaining the quality and performance of the machines throughout their lifecycle.

In conclusion, quality control is an integral part of the CNC laser cutting machine manufacturing process. By implementing strict quality control measures at every stage of production, manufacturers can ensure that their machines are reliable, efficient, and meet the highest industry standards. This not only helps in building a strong reputation in the market but also leads to increased customer satisfaction and long-term business success.

Import and Export Regulations for cnc laser cutting machine manufacturers

CNC laser cutting machine manufacturers are subject to various import and export regulations that govern the international trade of these high-tech machines. These regulations are in place to ensure the safety, quality, and proper use of these machines, as well as to protect the interests of the countries involved in the trade. In this article, we will briefly discuss some of the key import and export regulations that CNC laser cutting machine manufacturers need to be aware of.

1. Tariffs and Duties: Importing and exporting CNC laser cutting machines may be subject to customs duties and tariffs, depending on the country of origin and destination. Manufacturers must be aware of the applicable tariff rates and ensure that they are included in the pricing of their products. Failure to do so may result in penalties and additional costs.

2. Import and Export Licenses: Some countries may require import or export licenses for the trade of CNC laser cutting machines. Manufacturers must obtain the necessary licenses and permits before shipping their products to ensure compliance with local regulations.

3. Quality and Safety Standards: CNC laser cutting machines must meet specific quality and safety standards in the countries where they are sold. Manufacturers should be aware of these standards and ensure that their products comply with them. This may involve obtaining certifications or undergoing inspections by relevant authorities.

4. Intellectual Property Rights: Manufacturers must ensure that their CNC laser cutting machines do not infringe on any patents, trademarks, or copyrights in the countries where they are sold. This may involve conducting thorough research and obtaining licenses or permissions from the intellectual property rights holders.

5. Restricted or Prohibited Items: Some countries may have restrictions or prohibitions on the import or export of certain types of CNC laser cutting machines, particularly those that can be used for military or nuclear purposes. Manufacturers must be aware of these restrictions and ensure that their products do not fall under them.

6. Documentation and Record-Keeping: Manufacturers must maintain accurate records of their import and export transactions, including invoices, shipping documents, and customs declarations. These records may be subject to inspection by customs authorities and must be kept for a specified period.

In conclusion, CNC laser cutting machine manufacturers must be aware of and comply with various import and export regulations to ensure the smooth and legal trade of their products. Failure to do so may result in penalties, additional costs, and damage to the company’s reputation.

The Role of Agents and Sourcing Companies in Facilitating Purchases from cnc laser cutting machine manufacturers

Agents and sourcing companies play a crucial role in facilitating purchases from CNC laser cutting machine manufacturers. These intermediaries bridge the gap between buyers and manufacturers, ensuring a smooth and efficient transaction process. Their expertise in the industry, coupled with their extensive network of contacts, enables them to identify the best suppliers and negotiate favorable terms on behalf of their clients.

One of the primary roles of agents and sourcing companies is to identify and evaluate potential manufacturers. They conduct thorough research and assess the capabilities, product quality, and reliability of various CNC laser cutting machine manufacturers. This helps buyers make informed decisions and select the most suitable supplier for their needs.

Another key function of these intermediaries is to negotiate prices and contract terms with manufacturers. They leverage their industry knowledge and relationships to secure the best possible deals for their clients. This not only saves buyers time and effort but also ensures that they get the most value for their investment.

Agents and sourcing companies also assist in managing the logistics of the transaction. They coordinate with manufacturers to ensure timely production and delivery of the CNC laser cutting machines. This includes overseeing the shipping process, handling customs clearance, and ensuring that the machines arrive at their destination in good condition.

Furthermore, these intermediaries provide after-sales support and assistance. They act as a liaison between the buyer and the manufacturer, addressing any concerns or issues that may arise during the installation, operation, or maintenance of the CNC laser cutting machines. This ensures that buyers receive prompt and efficient support, minimizing downtime and maximizing productivity.

In conclusion, agents and sourcing companies play a vital role in facilitating purchases from CNC laser cutting machine manufacturers. They help buyers navigate the complex process of identifying, evaluating, and selecting suppliers, negotiating favorable terms, and managing logistics. By leveraging their industry expertise and extensive network of contacts, these intermediaries ensure a smooth and efficient transaction process, ultimately benefiting both buyers and manufacturers.

Supply Chain Management for cnc laser cutting machine manufacturers

Supply Chain Management (SCM) is a crucial aspect for CNC laser cutting machine manufacturers to ensure smooth operations, cost efficiency, and customer satisfaction. It involves the coordination and management of all activities involved in sourcing, procurement, conversion, and logistics management. The primary goal of SCM is to meet customer demands while minimizing costs and maximizing efficiency.

1. Sourcing and Procurement: CNC laser cutting machine manufacturers must identify and collaborate with reliable suppliers for raw materials, components, and sub-assemblies. This involves evaluating suppliers based on quality, cost, delivery time, and flexibility. Establishing long-term relationships with suppliers can lead to better pricing, priority treatment, and improved collaboration on product development.

2. Inventory Management: Efficient inventory management is essential to minimize holding costs, reduce lead times, and ensure the availability of materials and components for production. Manufacturers should implement inventory control systems, such as just-in-time (JIT) or vendor-managed inventory (VMI), to optimize stock levels and reduce the risk of stockouts or overstocking.

3. Production Planning and Scheduling: CNC laser cutting machine manufacturers must plan and schedule their production processes to meet customer demands while optimizing resource utilization. This involves forecasting demand, allocating resources, and setting production targets. Advanced planning and scheduling (APS) software can help manufacturers to balance demand and supply, minimize production costs, and improve on-time delivery performance.

4. Quality Management: Ensuring the quality of CNC laser cutting machines is vital for customer satisfaction and brand reputation. Manufacturers should implement robust quality management systems (QMS) to monitor and control product quality throughout the supply chain. This includes conducting regular inspections, audits, and tests to identify and address quality issues.

5. Logistics and Distribution: Efficient logistics and distribution processes are essential to deliver CNC laser cutting machines to customers on time and in perfect condition. Manufacturers should collaborate with reliable logistics partners to optimize transportation, warehousing, and distribution operations. This may involve implementing transportation management systems (TMS) and warehouse management systems (WMS) to improve visibility, reduce costs, and enhance customer service.

In conclusion, effective supply chain management is crucial for CNC laser cutting machine manufacturers to stay competitive and meet customer expectations. By optimizing sourcing, inventory management, production planning, quality management, and logistics processes, manufacturers can reduce costs, improve efficiency, and enhance customer satisfaction.

Negotiating with cnc laser cutting machine manufacturers

Subject: CNC Laser Cutting Machine Inquiry

Dear [Manufacturer’s Name],

I hope this message finds you well. I am writing to express my interest in purchasing a CNC laser cutting machine for my business, [Your Company Name]. We specialize in [Your Company’s Field], and we believe that your high-quality machines would greatly enhance our production capabilities.

Before proceeding with the purchase, I would like to discuss the following key points to ensure that we can reach a mutually beneficial agreement:

1. Pricing: We are looking for a competitive price for the CNC laser cutting machine. As we plan to make a long-term investment in your products, we hope to receive a favorable offer that reflects our commitment to a lasting partnership.

2. Customization: Our production requirements may necessitate certain modifications to the standard machine specifications. We would appreciate your flexibility in accommodating our specific needs and providing a tailored solution.

3. Warranty and Support: We understand that your machines come with a standard warranty. However, we would like to discuss the possibility of extending the warranty period and receiving additional technical support to ensure the smooth operation of the machine in our facility.

4. Training and Installation: To maximize the efficiency and safety of our operations, we request that your team provides comprehensive training for our staff on the proper use and maintenance of the machine. Additionally, we would like to inquire about the cost and timeline for the installation of the machine at our facility.

5. Payment Terms: We would like to negotiate favorable payment terms, such as an extended payment period or a discount for early payment, to ease the financial burden of this significant investment.

We are excited about the prospect of incorporating your CNC laser cutting machine into our production process and believe that your product will greatly contribute to our company’s growth. I look forward to your response and the opportunity to discuss these points further.

Thank you for your time and consideration.

Best regards,

[Your Name] [Your Company Name] [Your Contact Information]Protecting Intellectual Property When Working with cnc laser cutting machine manufacturers

Protecting intellectual property (IP) is crucial when working with CNC laser cutting machine manufacturers, as it ensures that your unique designs, ideas, and innovations are not misused or copied without your permission. Here are some steps you can take to protect your IP:

1. Non-Disclosure Agreements (NDAs): Before sharing any sensitive information or designs with a manufacturer, have them sign a non-disclosure agreement. This legally binding document ensures that the manufacturer cannot disclose or use your IP without your permission.

2. Intellectual Property Rights (IPR) Agreement: In addition to an NDA, you can also draft an IPR agreement that outlines the ownership and usage rights of your IP. This agreement should clearly state that you retain all rights to your IP and that the manufacturer is only allowed to use it for the specific purpose of producing your products.

3. Limit Access to Information: Only provide the manufacturer with the necessary information required for production. Avoid sharing any additional details or designs that are not directly related to the manufacturing process.

4. Monitor Production: Regularly monitor the production process to ensure that your IP is being used correctly and not being misused or copied. This can be done through on-site visits or by requesting regular updates and reports from the manufacturer.

5. Register Your IP: Register your intellectual property rights, such as patents, trademarks, and copyrights, in the countries where you plan to sell your products. This will provide you with legal protection and the ability to take action against any infringement.

6. Choose Reputable Manufacturers: Work with well-established and reputable CNC laser cutting machine manufacturers who have a track record of respecting their clients’ IP. Conduct thorough research and seek recommendations from industry peers before selecting a manufacturer.

7. Maintain Clear Communication: Establish open and clear communication with the manufacturer to ensure that they understand the importance of protecting your IP and the consequences of any infringement.

By taking these precautions, you can significantly reduce the risk of your intellectual property being misused or copied when working with CNC laser cutting machine manufacturers. This will help safeguard your competitive advantage and ensure the long-term success of your business.

Avoiding Scams When Working with cnc laser cutting machine manufacturers

When working with CNC laser cutting machine manufacturers, it is essential to take precautions to avoid scams and ensure a successful business transaction. Here are some tips to help you avoid scams when working with these manufacturers:

1. Research the company: Before engaging with a manufacturer, conduct thorough research on the company. Check their website, online reviews, and any available testimonials from previous clients. Look for any red flags, such as a lack of contact information, poor website design, or negative reviews.

2. Verify the company’s legitimacy: Check if the company is registered and has the necessary certifications to operate in their industry. You can usually find this information on their website or by contacting the relevant government agency in their country.

3. Ask for references: Request a list of previous clients or projects the manufacturer has worked on. Contact these references to inquire about their experience working with the manufacturer and the quality of the products they received.

4. Request samples: Before committing to a large order, ask the manufacturer for samples of their work. This will give you an idea of the quality of their products and help you determine if they meet your standards.

5. Use secure payment methods: Avoid making payments through unsecured methods, such as wire transfers or direct deposits. Instead, use secure payment platforms like PayPal or a letter of credit from your bank.

6. Get everything in writing: Make sure to have a written contract outlining the terms of your agreement with the manufacturer. This should include details about the product specifications, payment terms, delivery timeline, and any warranties or guarantees.

7. Inspect the products upon delivery: When you receive your order, inspect the products thoroughly to ensure they meet your specifications and quality standards. If you notice any issues, contact the manufacturer immediately to address the problem.

8. Monitor the manufacturing process: If possible, visit the manufacturer’s facility to observe the production process and ensure they are using the proper equipment and materials. This can help you verify that the manufacturer is capable of producing high-quality products.

9. Be cautious of unusually low prices: If a manufacturer offers a price that seems too good to be true, it may be a red flag. Low prices could indicate poor quality materials or a lack of experience in the industry.

10. Trust your instincts: If something feels off about a manufacturer or the way they conduct business, trust your instincts and consider looking for another supplier.

By following these tips, you can minimize the risk of scams and ensure a successful partnership with a CNC laser cutting machine manufacturer.

How to use import and export data website importyeti.com to search the company and cnc laser cutting machine manufacturers

ImportYeti is a powerful tool that allows users to search and analyze import/export data of various companies. To search for a company and CNC laser cutting machine manufacturers, follow these simple steps:

1. Visit importyeti.com: Open your preferred web browser and navigate to the ImportYeti website (https://www.importyeti.com/).

2. Search for a company: On the homepage, you will see a search bar. Type the name of the company you are looking for and click the “Search” button. If you don’t have a specific company in mind, you can type keywords related to CNC laser cutting machine manufacturers, such as “CNC laser cutting” or “laser cutting machine.”

3. Browse search results: ImportYeti will display a list of companies that match your search query. Browse through the results to find the company or manufacturer you are interested in. You can click on the company name to view more details about their import/export activities.

4. Analyze company data: Once you have selected a company, you will be presented with various data points, such as their top products, top customers, and top suppliers. This information can help you understand the company’s business activities and identify potential CNC laser cutting machine manufacturers.

5. Export data: If you want to save the data for further analysis, you can export it in various formats, such as CSV, Excel, or PDF. Click on the “Export” button located at the top right corner of the page and choose your preferred format.

6. Refine your search: If you want to narrow down your search results, you can use the filters available on the left side of the search results page. You can filter by country, shipment date, HS code, and more. This will help you find the most relevant CNC laser cutting machine manufacturers for your needs.

In summary, ImportYeti is a valuable resource for searching and analyzing import/export data of companies and manufacturers. By following these steps, you can easily find CNC laser cutting machine manufacturers and gain insights into their business activities.

How to use Chinese Business Search Platform: qcc.com to check cnc laser cutting machine manufacturers company credit

Qcc.com is a Chinese business search platform that provides information on companies, including their credit status and other relevant details. To check the credit of CNC laser cutting machine manufacturers on qcc.com, follow these steps:

1. Access the website: Open your web browser and visit the qcc.com website.

2. Language selection: The website is primarily in Chinese, so you may need to use a translation tool like Google Translate to navigate the site. Right-click on the page and select “Translate to English” or use the translation extension in your browser.

3. Search for the company: In the search bar at the top of the page, type in the name of the CNC laser cutting machine manufacturer you want to check. Press Enter or click the search icon to initiate the search.

4. Browse search results: The search results will display a list of companies that match your query. Look for the correct company in the list, paying attention to the company’s name, location, and other identifying information. Click on the company’s name to access its profile.

5. Company profile: On the company profile page, you will find various information about the company, such as its registration number, legal representative, registered capital, and establishment date. This information can help you verify the legitimacy of the company.

6. Credit information: Scroll down the company profile page to find the credit information section. This section will provide details on the company’s credit status, including its credit score, credit rating, and any historical credit-related issues.

7. Financial data: The company profile page also provides financial data, such as revenue, net profit, and total assets. This information can help you assess the financial stability of the CNC laser cutting machine manufacturer.

8. Legal and risk information: Check the legal and risk information section on the company profile page for any lawsuits, administrative penalties, or other risk factors that may impact the company’s creditworthiness.

9. Export the information: If you want to save the company’s credit information for future reference, you can export the data as a PDF or Excel file by clicking the corresponding buttons on the company profile page.

By following these steps, you can use qcc.com to check the credit of CNC laser cutting machine manufacturers in China, helping you make informed decisions when selecting a supplier or business partner.

How to use archive.org to check cnc laser cutting machine manufacturers business website history

Archive.org, also known as the Wayback Machine, is a digital archive that allows users to view the history of websites. It can be a useful tool for researching the background of CNC laser cutting machine manufacturers and their business websites. Here’s a step-by-step guide on how to use archive.org to check a manufacturer’s website history:

1. Visit archive.org: Open your web browser and go to the Archive.org website (https://archive.org/).

2. Locate the Wayback Machine search bar: On the homepage, you will find a search bar labeled “Wayback Machine.” This is where you will enter the URL of the CNC laser cutting machine manufacturer’s website.

3. Enter the website URL: Type or paste the URL of the manufacturer’s website into the search bar. Make sure to include the “http://” or “https://” prefix. Then, click on the “Browse History” button or press Enter.

4. View the website history: The Wayback Machine will display a calendar view of the website’s history, with blue or green circles on the dates when the website was archived. The more circles you see, the more snapshots of the website are available.

5. Select a date: Click on a year at the top of the calendar to view the archived snapshots for that year. Then, click on a specific date with a colored circle to see the website as it appeared on that day.

6. Analyze the website content: Browse through the archived versions of the website to gather information about the CNC laser cutting machine manufacturer’s history, products, services, and any changes they have made over time. This can help you determine the company’s credibility, experience, and growth in the industry.

7. Compare different versions: You can use the navigation buttons at the top of the archived website page to move between different dates and compare the changes made to the website over time.

By following these steps, you can effectively use archive.org to research the history of CNC laser cutting machine manufacturers’ business websites and gain valuable insights into their background and experience in the industry.

Why contact sourcifyChina.com get free quota from reliable cnc laser cutting machine manufacturers?

Contacting SourcifyChina.com to get a free quote from reliable CNC laser cutting machine manufacturers is a smart move for several reasons. With the rapid growth of the manufacturing industry in China, it has become a hub for high-quality and cost-effective production. By reaching out to SourcifyChina.com, you can tap into this vast network of manufacturers and suppliers, ensuring that you get the best possible deal on your CNC laser cutting machine.

One of the main advantages of using SourcifyChina.com is that they have a team of experts who are well-versed in the Chinese manufacturing industry. They have established relationships with numerous reliable manufacturers, which means they can quickly identify the best options for your specific needs. This saves you time and effort in researching and vetting potential suppliers on your own.

Another benefit of using SourcifyChina.com is that they can help you negotiate the best possible price for your CNC laser cutting machine. Their team has extensive experience in dealing with Chinese manufacturers, which means they know how to get the best deals on your behalf. This can result in significant cost savings for your business.

In addition to helping you find the right manufacturer and negotiate the best price, SourcifyChina.com can also assist with quality control and logistics. They can ensure that the CNC laser cutting machine you receive meets your specifications and is of the highest quality. Furthermore, they can help arrange shipping and customs clearance, making the entire process of sourcing your CNC laser cutting machine from China smooth and hassle-free.

In conclusion, contacting SourcifyChina.com to get a free quote from reliable CNC laser cutting machine manufacturers is a wise decision because it allows you to leverage their expertise, connections, and experience in the Chinese manufacturing industry. This can result in significant cost savings, high-quality products, and a streamlined sourcing process, making it an excellent option for businesses looking to source CNC laser cutting machines from China.