Fiber Laser Cutting Machine Manufacturer

Benefits

The fiber laser cutting machine offers numerous advantages for businesses and individuals alike. These benefits include:

1. High precision and accuracy: Fiber laser cutting machines provide precise and accurate cuts, ensuring that your finished products are of the highest quality.

2. Increased efficiency: With faster cutting speeds and the ability to cut multiple materials, fiber laser cutting machines can significantly improve your production efficiency.

3. Lower operating costs: Fiber laser cutting machines require less maintenance and have a longer lifespan than traditional cutting methods, reducing your overall operating costs.

4. Eco-friendly: Fiber laser cutting machines produce less waste and consume less energy, making them an environmentally friendly option for your business.

Features

Some of the standout features of fiber laser cutting machines include:

1. High cutting speed: Fiber laser cutting machines can cut materials at a much faster rate than traditional cutting methods.

2. Wide range of materials: These machines can cut a variety of materials, including metal, plastic, and wood.

3. Advanced software: Fiber laser cutting machines come equipped with advanced software that allows for easy programming and operation.

4. Compact design: The compact design of fiber laser cutting machines makes them suitable for small workshops and businesses with limited space.

Specifications

Key specifications of fiber laser cutting machines include:

1. Laser power: Ranging from 500W to 12,000W, depending on the model and application.

2. Cutting area: Varies depending on the model, with larger machines capable of cutting larger sheets of material.

3. Cutting thickness: Capable of cutting materials up to 25mm thick, depending on the laser power and material type.

4. Positioning accuracy: ±0.03mm to ensure precise and accurate cuts.

Applications

Fiber laser cutting machines are used in a wide range of industries and applications, such as:

1. Automotive: Cutting and shaping metal components for cars and other vehicles.

2. Aerospace: Precision cutting of aircraft components and parts.

3. Manufacturing: Cutting and shaping various materials for use in the production of goods.

4. Signage: Creating custom signs and logos from metal, plastic, and other materials.

5. Art and design: Cutting intricate designs and patterns for use in artistic and decorative projects.

FAQ

1. What materials can a fiber laser cutting machine cut?

Fiber laser cutting machines can cut a wide range of materials, including metal, plastic, and wood.

2. How thick can a fiber laser cutting machine cut?

The cutting thickness depends on the laser power and material type, with some machines capable of cutting materials up to 25mm thick.

3. What is the lifespan of a fiber laser cutting machine?

Fiber laser cutting machines typically have a longer lifespan than traditional cutting methods, with some machines lasting up to 100,000 hours of use.

4. How do I maintain my fiber laser cutting machine?

Regular maintenance, such as cleaning the lens and checking the alignment, can help ensure your machine continues to operate at peak performance. Always consult your machine’s user manual for specific maintenance instructions.

5. What kind of software do I need to operate a fiber laser cutting machine?

Fiber laser cutting machines come equipped with advanced software that allows for easy programming and operation. This software

A Beginner’s Guide to fiber laser cutting machine manufacturer

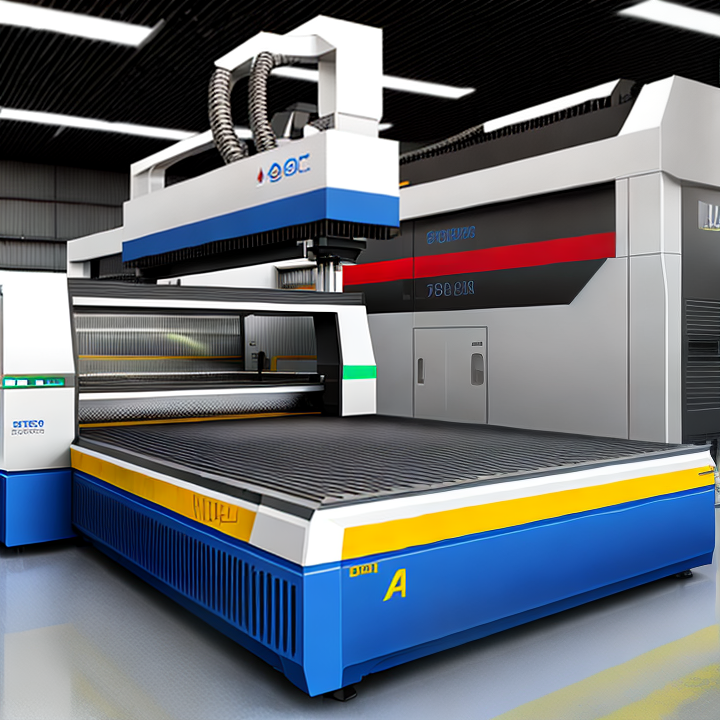

A fiber laser cutting machine is a type of industrial equipment used for cutting various materials, such as metal, plastic, and wood, with high precision and speed. Fiber laser cutting machines are widely used in industries like automotive, aerospace, electronics, and manufacturing. As a beginner, it is essential to understand the basics of fiber laser cutting machines and how to choose the right manufacturer.

1. Working Principle: Fiber laser cutting machines use a high-powered laser beam to cut through materials. The laser beam is generated by a fiber laser source and focused onto the material surface using a lens. The heat from the laser beam melts or vaporizes the material, resulting in a precise cut.

2. Types of Fiber Laser Cutting Machines: There are two main types of fiber laser cutting machines – flatbed and tube cutting machines. Flatbed machines are used for cutting flat materials, while tube cutting machines are designed for cutting cylindrical or tubular materials.

3. Key Components: A fiber laser cutting machine consists of several key components, including the fiber laser source, cutting head, CNC (Computer Numerical Control) system, and a working table. The fiber laser source generates the laser beam, the cutting head focuses the beam onto the material, the CNC system controls the movement of the cutting head, and the working table holds the material in place.

4. Choosing a Manufacturer: When selecting a fiber laser cutting machine manufacturer, consider factors such as the company’s reputation, experience, product quality, and after-sales service. Research and compare different manufacturers to find the one that best suits your needs and budget. Some well-known fiber laser cutting machine manufacturers include Trumpf, Bystronic, Amada, and IPG Photonics.

5. Training and Maintenance: Operating a fiber laser cutting machine requires proper training to ensure safety and efficiency. Make sure the manufacturer provides adequate training and support. Regular maintenance is also crucial to keep the machine in optimal condition and prolong its lifespan.

In conclusion, understanding the basics of fiber laser cutting machines and choosing the right manufacturer is essential for beginners in the industry. Consider factors such as the type of machine, key components, manufacturer reputation, and after-sales service when making your decision.

How to Select a Reliable fiber laser cutting machine manufacturer

Selecting a reliable fiber laser cutting machine manufacturer is crucial for ensuring the quality, efficiency, and longevity of the equipment. Here are some key factors to consider when choosing a manufacturer:

1. Reputation and experience: Look for a manufacturer with a solid reputation in the industry and a proven track record of producing high-quality fiber laser cutting machines. Check for customer reviews, testimonials, and case studies to gauge their credibility. A manufacturer with several years of experience is more likely to have refined their products and processes.

2. Technical expertise: The manufacturer should have a team of skilled engineers and technicians with in-depth knowledge of fiber laser technology. They should be able to provide expert advice on the best machine for your specific needs and offer customized solutions if required.

3. Quality certifications: Ensure that the manufacturer adheres to international quality standards and holds relevant certifications, such as ISO 9001. This indicates that they have a robust quality management system in place and are committed to producing high-quality products.

4. After-sales support: A reliable manufacturer should offer comprehensive after-sales support, including installation, training, maintenance, and repair services. They should also provide prompt and efficient customer service to address any issues or concerns.

5. Warranty and spare parts availability: Check the warranty terms offered by the manufacturer and ensure that they provide readily available spare parts for their machines. This will minimize downtime and ensure the smooth operation of your fiber laser cutting machine.

6. Product range: A manufacturer with a wide range of fiber laser cutting machines is more likely to have a solution that fits your specific requirements. Compare the features, specifications, and prices of different models to make an informed decision.

7. Local presence: If possible, choose a manufacturer with a local presence or a strong network of distributors and service centers in your region. This will ensure easier access to technical support, spare parts, and maintenance services.

In summary, selecting a reliable fiber laser cutting machine manufacturer involves researching their reputation, experience, technical expertise, quality certifications, after-sales support, warranty terms, product range, and local presence. By considering these factors, you can make an informed decision and invest in a high-quality machine that meets your needs.

Comparing fiber laser cutting machine manufacturer and Suppliers: Which is Better?

When comparing fiber laser cutting machine manufacturers and suppliers, it is essential to consider several factors to determine which option is better for your specific needs. Here are some key aspects to consider:

1. Quality and Performance: The quality and performance of the fiber laser cutting machines should be your top priority. Look for manufacturers and suppliers with a proven track record of producing high-quality, reliable machines. Check for certifications, such as ISO and CE, which indicate adherence to international quality standards.

2. Technical Support and Service: A good manufacturer or supplier should offer comprehensive technical support and after-sales service. This includes installation, training, maintenance, and troubleshooting. Make sure the company has a dedicated team of experienced technicians who can provide prompt and efficient support.

3. Customization and Flexibility: Depending on your specific requirements, you may need a fiber laser cutting machine with specific features or capabilities. Look for manufacturers and suppliers that offer customization options and can tailor their machines to meet your unique needs.

4. Price and Value for Money: While the price is an important factor, it should not be the sole determinant in your decision. Instead, focus on the overall value for money, taking into account the quality, performance, support, and customization options offered by the manufacturer or supplier.

5. Reputation and Reviews: Research the reputation of the manufacturer or supplier by reading customer reviews and testimonials. This will give you an idea of the company’s reliability, customer satisfaction, and overall performance.

6. Warranty and Spare Parts Availability: A good manufacturer or supplier should offer a warranty on their fiber laser cutting machines and have spare parts readily available. This ensures that you can quickly resolve any issues and minimize downtime.

In conclusion, there is no one-size-fits-all answer to which is better between fiber laser cutting machine manufacturers and suppliers. It ultimately depends on your specific needs and priorities. By considering the factors mentioned above, you can make an informed decision and choose the best option for your business.

The Manufacturing Process of fiber laser cutting machine manufacturer

The manufacturing process of a fiber laser cutting machine involves several key steps, which are crucial to ensure the high precision, efficiency, and durability of the final product. These steps include design and development, material selection and preparation, component manufacturing, assembly, testing, and quality control.

1. Design and Development: The first step in the manufacturing process is the design and development of the fiber laser cutting machine. This involves creating a detailed blueprint of the machine, including its dimensions, specifications, and features. Engineers and designers use computer-aided design (CAD) software to create these blueprints, ensuring that all components are designed to work together seamlessly.

2. Material Selection and Preparation: Once the design is finalized, the appropriate materials are selected for the various components of the machine. These materials typically include metals such as stainless steel, aluminum, and brass, as well as high-quality optical components like mirrors and lenses. The materials are then prepared for manufacturing by cutting, shaping, and cleaning them.

3. Component Manufacturing: The individual components of the fiber laser cutting machine are manufactured using various techniques, such as CNC machining, laser cutting, and sheet metal bending. These processes ensure that each component is made to the exact specifications outlined in the design.

4. Assembly: After all the components have been manufactured, they are assembled to create the final fiber laser cutting machine. This involves carefully aligning and securing the various parts, such as the laser source, cutting head, control system, and motion system. The assembly process requires skilled technicians to ensure that the machine is built to the highest standards of precision and quality.

5. Testing: Once the machine is assembled, it undergoes rigorous testing to ensure that it functions correctly and meets all performance specifications. This includes testing the laser’s power output, cutting speed, and accuracy, as well as the machine’s overall stability and reliability.

6. Quality Control: The final step in the manufacturing process is quality control, which involves inspecting the completed fiber laser cutting machine for any defects or issues. This includes checking for proper alignment, smooth operation, and adherence to safety standards. Any issues found during quality control are addressed and corrected before the machine is shipped to the customer.

In conclusion, the manufacturing process of a fiber laser cutting machine is a complex and precise endeavor that requires careful planning, skilled craftsmanship, and strict quality control measures. By following these steps, manufacturers can produce high-quality, reliable machines that meet the needs of various industries and applications.

Custom Manufacturing Options for fiber laser cutting machine manufacturer

Fiber laser cutting machine manufacturers offer a wide range of custom manufacturing options to cater to the diverse needs of their clients. These options enable businesses to optimize their production processes, reduce costs, and improve overall efficiency. Here are some of the most popular custom manufacturing options available:

1. Customized machine size: Manufacturers can design and build fiber laser cutting machines with varying sizes and dimensions to suit the specific requirements of a client’s production facility. This ensures that the machine fits seamlessly into the existing workspace and can handle the required workload.

2. Power options: Fiber laser cutting machines are available in different power capacities, ranging from low-power models for small-scale operations to high-power models for heavy-duty industrial applications. Clients can choose the most suitable power capacity based on their production needs and budget constraints.

3. Automation integration: Manufacturers can integrate various automation features into the fiber laser cutting machines, such as automatic loading and unloading systems, robotic arms, and conveyor systems. These features help streamline the production process, reduce manual labor, and increase overall efficiency.

4. Customized software: Fiber laser cutting machine manufacturers can develop customized software solutions tailored to the specific needs of a client’s production process. This software can include features such as advanced nesting algorithms, material management systems, and production scheduling tools.

5. Specialized cutting heads: Depending on the materials being processed and the desired cutting quality, manufacturers can equip the fiber laser cutting machines with specialized cutting heads. These cutting heads can be designed for specific applications, such as cutting thick materials, processing reflective materials, or achieving high-precision cuts.

6. Additional accessories: Manufacturers can also provide additional accessories and attachments to enhance the functionality of the fiber laser cutting machines. These can include protective covers, dust extraction systems, and air filtration units, among others.

7. Training and support: To ensure that clients can effectively operate and maintain their fiber laser cutting machines, manufacturers can offer comprehensive training and support services. This can include on-site training, remote assistance, and access to online resources.

In conclusion, fiber laser cutting machine manufacturers offer a wide range of custom manufacturing options to meet the unique needs of their clients. By choosing the right combination of features and capabilities, businesses can optimize their production processes, reduce costs, and improve overall efficiency.

Quality Control in fiber laser cutting machine manufacturer

Quality control is an essential aspect of the manufacturing process for fiber laser cutting machines. It ensures that the machines produced meet the required standards and specifications, resulting in high-quality products that satisfy customer needs. Manufacturers must implement a comprehensive quality control system to maintain the performance, reliability, and safety of their fiber laser cutting machines.

1. Material inspection: Quality control begins with the inspection of raw materials used in the production of fiber laser cutting machines. Suppliers must provide materials that meet the required standards, and manufacturers should conduct thorough inspections to ensure their quality and consistency.

2. Process control: Manufacturers must establish strict process control measures to ensure that each stage of production is carried out according to the set guidelines. This includes monitoring and controlling the cutting, welding, and assembly processes to maintain the accuracy and precision of the final product.

3. In-process inspection: Regular inspections should be conducted during the production process to identify any potential defects or deviations from the set standards. This allows for timely corrective actions to be taken, preventing the production of substandard machines.

4. Testing and calibration: Before shipping, fiber laser cutting machines must undergo rigorous testing and calibration to ensure their performance, accuracy, and reliability. This includes testing the machine’s cutting speed, accuracy, and repeatability, as well as calibrating the machine’s components, such as the laser source, cutting head, and control system.

5. Training and certification: Manufacturers should invest in the training and certification of their quality control personnel to ensure they have the necessary skills and knowledge to effectively carry out their duties. This includes training in quality management systems, inspection techniques, and the use of testing equipment.

6. Continuous improvement: Quality control is an ongoing process that requires constant monitoring and improvement. Manufacturers should regularly review their quality control processes, identify areas for improvement, and implement corrective actions to ensure the continuous production of high-quality fiber laser cutting machines.

In conclusion, quality control is a critical aspect of fiber laser cutting machine manufacturing. By implementing a comprehensive quality control system, manufacturers can ensure the production of high-quality machines that meet customer expectations and maintain their competitive edge in the market.

Import and Export Regulations for fiber laser cutting machine manufacturer

Fiber laser cutting machines are advanced pieces of equipment used in various industries for precise cutting and engraving of metals and other materials. As a manufacturer of these machines, it is crucial to be aware of the import and export regulations that govern the international trade of such equipment. These regulations are in place to ensure the safety, quality, and proper use of these machines, as well as to prevent their misuse for illegal purposes.

1. Compliance with International Standards: As a manufacturer, it is essential to ensure that your fiber laser cutting machines comply with international standards such as ISO, CE, and other relevant certifications. These certifications not only ensure the quality and safety of your products but also facilitate smooth import and export processes.

2. Export Control Regulations: Fiber laser cutting machines may be subject to export control regulations due to their potential dual-use nature. These machines can be used for both civilian and military purposes, and therefore, their export may be restricted or controlled by the government. It is crucial to check the export control regulations in your country and the destination country to ensure compliance.

3. Import Regulations: The import regulations for fiber laser cutting machines may vary from country to country. Some countries may require specific permits, licenses, or certifications for the import of such equipment. It is essential to research and comply with the import regulations of the destination country to avoid any legal issues or delays in the shipment process.

4. Customs Duties and Taxes: Importing and exporting fiber laser cutting machines may be subject to customs duties and taxes. These charges vary depending on the country and the value of the equipment. It is essential to be aware of the applicable duties and taxes to avoid any unexpected costs during the import or export process.

5. Intellectual Property Rights: As a manufacturer, it is crucial to protect your intellectual property rights, such as patents, trademarks, and copyrights. Ensure that your products do not infringe on any existing intellectual property rights in the destination country to avoid legal disputes and potential penalties.

In conclusion, as a fiber laser cutting machine manufacturer, it is essential to be aware of and comply with the import and export regulations governing the international trade of such equipment. This includes ensuring compliance with international standards, export control regulations, import regulations, customs duties and taxes, and intellectual property rights. By adhering to these regulations, you can ensure the smooth and legal trade of your products in the global market.

The Role of Agents and Sourcing Companies in Facilitating Purchases from fiber laser cutting machine manufacturer

Agents and sourcing companies play a crucial role in facilitating purchases from fiber laser cutting machine manufacturers. These intermediaries act as a bridge between the buyer and the manufacturer, ensuring a smooth and efficient transaction process. In this competitive market, their expertise and services are essential for buyers to make informed decisions and secure the best deals.

Firstly, agents and sourcing companies have extensive knowledge of the market and the various manufacturers. They can identify the most suitable fiber laser cutting machine manufacturers based on the buyer’s requirements, budget, and preferences. This saves time and effort for the buyer, who may not have the resources or expertise to navigate the complex market independently.

Secondly, these intermediaries have established relationships with manufacturers, which can be advantageous for buyers. They can negotiate better prices, secure exclusive deals, and ensure timely delivery of the machines. This is particularly beneficial for small and medium-sized businesses that may not have the bargaining power to negotiate directly with manufacturers.

Thirdly, agents and sourcing companies can provide valuable assistance in quality control and inspection. They can visit the manufacturing facilities, inspect the machines, and ensure that they meet the buyer’s specifications and quality standards. This reduces the risk of receiving substandard or defective products, which can be costly and time-consuming to rectify.

Additionally, these intermediaries can help with logistics and shipping arrangements. They can coordinate with the manufacturer and the shipping company to ensure that the fiber laser cutting machines are delivered safely and on time. This is particularly important for international buyers, who may face challenges with customs clearance, import regulations, and transportation.

Lastly, agents and sourcing companies can provide after-sales support and assistance. They can help with the installation, maintenance, and repair of the fiber laser cutting machines, ensuring that the buyer receives the best possible service and support throughout the life of the machine.

In conclusion, agents and sourcing companies play a vital role in facilitating purchases from fiber laser cutting machine manufacturers. Their expertise, relationships, and services help buyers navigate the complex market, secure the best deals, and ensure a smooth and efficient transaction process.

Supply Chain Management for fiber laser cutting machine manufacturer

Supply Chain Management (SCM) is a crucial aspect for any manufacturing company, including a fiber laser cutting machine manufacturer. It involves the efficient management of the entire supply chain process, from sourcing raw materials to delivering the final product to the customer. The primary objective of SCM is to minimize costs, optimize resources, and ensure timely delivery of products while maintaining high quality standards.

For a fiber laser cutting machine manufacturer, the supply chain process can be divided into four main stages: procurement, production, distribution, and customer service.

1. Procurement: The first step in the supply chain is procuring raw materials and components required for manufacturing fiber laser cutting machines. This involves identifying and selecting reliable suppliers, negotiating contracts, and managing inventory levels. The manufacturer must ensure that the suppliers meet quality standards and can deliver materials on time to avoid production delays.

2. Production: The next stage is the actual manufacturing of the fiber laser cutting machines. This involves transforming raw materials into finished products through various processes such as cutting, welding, and assembling. The manufacturer must ensure that the production process is efficient and cost-effective, while maintaining high quality standards. This can be achieved through lean manufacturing techniques, automation, and continuous improvement initiatives.

3. Distribution: Once the fiber laser cutting machines are manufactured, they need to be transported to the customers. This involves managing logistics, warehousing, and transportation. The manufacturer must ensure that the machines are delivered on time and in perfect condition. This can be achieved through efficient transportation planning, real-time tracking of shipments, and partnering with reliable logistics providers.

4. Customer Service: The final stage in the supply chain is providing after-sales support to the customers. This includes installation, training, maintenance, and repair services. The manufacturer must ensure that the customers are satisfied with the product and the support provided. This can be achieved through timely and efficient customer service, regular follow-ups, and addressing customer concerns promptly.

In conclusion, effective supply chain management is essential for a fiber laser cutting machine manufacturer to stay competitive in the market. By optimizing procurement, production, distribution, and customer service processes, the manufacturer can reduce costs, improve efficiency, and ensure customer satisfaction. This, in turn, will lead to increased sales, higher profits, and long-term business success.

Negotiating with fiber laser cutting machine manufacturer

Subject: Fiber Laser Cutting Machine Inquiry and Negotiation

Dear [Manufacturer’s Name],

I hope this message finds you well. I am writing to express my interest in your fiber laser cutting machines and to discuss the possibility of negotiating a mutually beneficial deal for both our companies.

Our company, [Your Company’s Name], specializes in [Your Company’s Field], and we are currently in the process of expanding our production capabilities. We believe that your fiber laser cutting machines would be a valuable addition to our operations, and we are particularly interested in the [Specific Model Name] model.

Before proceeding further, I would like to request a detailed quotation for the [Specific Model Name], including the base price, any available discounts, shipping costs, and lead time for delivery. Additionally, please provide information on warranty terms, after-sales support, and any training or installation services that you offer.

We understand that the current market price for the [Specific Model Name] is around [Market Price], but we would like to explore the possibility of negotiating a more competitive price. As a growing company, we are looking to establish long-term relationships with reliable suppliers, and we believe that your company could be an ideal partner for us. In return for a favorable price, we can commit to purchasing a certain volume of machines over a specified period, which would guarantee a steady stream of business for your company.

Furthermore, we would be happy to promote your brand and products within our industry network, potentially leading to increased sales and exposure for your company. We believe that this collaboration could be mutually beneficial and strengthen the business relationship between our companies.

Please let us know your thoughts on our proposal and if you are open to negotiating the terms. We are eager to work with you and look forward to your prompt response.

Thank you for your time and consideration.

Best regards,

[Your Name] [Your Company’s Name] [Your Contact Information]Protecting Intellectual Property When Working with fiber laser cutting machine manufacturer

Protecting intellectual property (IP) is crucial when working with any manufacturer, including fiber laser cutting machine manufacturers. IP refers to creations of the mind, such as inventions, designs, and artistic works, which are protected by patents, trademarks, copyrights, and trade secrets. Here are some steps to ensure the protection of your IP when working with a fiber laser cutting machine manufacturer:

1. Non-disclosure agreements (NDAs): Before sharing any sensitive information or designs with the manufacturer, ensure that both parties sign a non-disclosure agreement. This legally binding document ensures that the manufacturer will not disclose or use your confidential information for any purpose other than the agreed-upon project.

2. Patents and trademarks: If your design or invention is unique and has commercial potential, consider applying for a patent or trademark to protect your IP. This will grant you exclusive rights to use, manufacture, and sell your invention or design for a specified period.

3. Limit information sharing: Share only the necessary information with the manufacturer to complete the project. Avoid disclosing trade secrets or any other sensitive information that could be used to replicate your product or design.

4. Monitor production: Regularly monitor the production process to ensure that the manufacturer is adhering to your specifications and not using your IP for any unauthorized purposes. This can be done through on-site visits or by hiring a third-party inspection company to oversee the production process.

5. Contractual agreements: Ensure that your contract with the manufacturer includes clauses that protect your IP rights. This may include provisions that prohibit the manufacturer from using your IP for any purpose other than the agreed-upon project, as well as penalties for any breaches of the agreement.

6. Choose a reputable manufacturer: Conduct thorough research and due diligence when selecting a fiber laser cutting machine manufacturer. Choose a company with a strong track record of respecting IP rights and maintaining confidentiality.

7. Register your IP in the manufacturer’s country: If the manufacturer is located in a different country, consider registering your IP in that country as well. This will provide additional legal protection in case of any disputes or infringements.

By taking these precautions, you can minimize the risk of IP theft and ensure that your valuable intellectual property remains protected when working with a fiber laser cutting machine manufacturer.

Avoiding Scams When Working with fiber laser cutting machine manufacturer

When working with fiber laser cutting machine manufacturers, it is crucial to take necessary precautions to avoid scams and ensure a successful business transaction. Here are some tips to help you avoid scams when working with these manufacturers:

1. Research the manufacturer: Before engaging with a manufacturer, conduct thorough research on their background, reputation, and experience in the industry. Look for customer reviews, testimonials, and any red flags that may indicate a potential scam. Check if the company is registered and has a valid business license.

2. Verify contact information: Ensure that the manufacturer’s contact information, including their physical address, phone number, and email address, is legitimate. Be cautious of companies that only provide an email address or use free email services, as this may be a sign of a scam.

3. Ask for references: Request a list of references from the manufacturer, including previous clients who have worked with them. Contact these references to inquire about their experiences and satisfaction with the manufacturer’s products and services.

4. Request samples and documentation: Before placing a large order, ask for samples of the manufacturer’s products to verify their quality and performance. Additionally, request documentation such as product specifications, certifications, and warranty information to ensure that the products meet your requirements and industry standards.

5. Use secure payment methods: When making payments, use secure methods such as bank transfers or reputable third-party payment platforms. Avoid using cash, personal checks, or untraceable payment methods, as these can be difficult to recover in case of a scam.

6. Sign a contract: Before starting any work with the manufacturer, sign a detailed contract outlining the terms and conditions of the project, including payment terms, delivery timelines, and quality expectations. This will provide legal protection in case of any disputes or issues.

7. Monitor progress: Stay in regular communication with the manufacturer throughout the project to monitor progress and address any concerns or issues that may arise. Request updates and photos of the production process to ensure that the project is on track and meeting your expectations.

8. Conduct quality inspections: Before accepting the final product, conduct a thorough quality inspection to ensure that the fiber laser cutting machines meet your specifications and standards. If possible, visit the manufacturing facility in person or hire a third-party inspection company to perform the inspection on your behalf.

By following these tips, you can minimize the risk of scams and ensure a successful partnership with a fiber laser cutting machine manufacturer.

How to use import and export data website importyeti.com to search the company and fiber laser cutting machine manufacturer

ImportYeti is a powerful tool that allows users to search and analyze import/export data of various companies. To search for a company and fiber laser cutting machine manufacturer, follow these simple steps:

1. Visit importyeti.com: Open your web browser and navigate to the ImportYeti website (https://www.importyeti.com/).

2. Use the search bar: On the homepage, you will find a search bar. Type the name of the company or the product (fiber laser cutting machine) you are looking for and click on the search icon.

3. Filter the search results: After clicking on the search icon, you will be presented with a list of companies and manufacturers related to your search query. You can filter the results by selecting the country of origin, destination, or other relevant filters available on the left side of the page.

4. Analyze the company details: Once you have found a company or manufacturer that matches your search criteria, click on their name to view more information. You will be able to see details such as the company’s address, contact information, shipment data, and more.

5. Review shipment data: On the company’s profile page, you can view their shipment data, including the product description, HS code, shipment date, and shipment destination. This information can help you determine if the company is a reliable fiber laser cutting machine manufacturer.

6. Export data: If you want to save the data for further analysis, you can export it in CSV format by clicking on the “Export” button located at the top right corner of the page. This feature is available for registered users, so you may need to sign up for a free account to access it.

By following these steps, you can efficiently search for a company and fiber laser cutting machine manufacturer using ImportYeti. The platform provides valuable insights into the import/export activities of companies, helping you make informed decisions when sourcing products or partnering with manufacturers.

How to use Chinese Business Search Platform: qcc.com to check fiber laser cutting machine manufacturer company credit

1. Open the QCC website: Go to the QCC (企查查) website at www.qcc.com. This is a popular Chinese business search platform that provides information on Chinese companies, including their credit status, registration details, and other relevant data.

2. Language selection: The default language of the website is Chinese. If you are not familiar with Chinese, you can use Google Chrome’s built-in translation feature to translate the website into English or your preferred language.

3. Register for an account: To access the full features of QCC, you need to register for a free account. Click on the “Register” button at the top right corner of the homepage and follow the instructions to create an account.

4. Search for the company: Once you have registered and logged in, enter the name of the fiber laser cutting machine manufacturer you want to check in the search bar at the top of the page. Press “Enter” or click the search icon to start the search.

5. Browse the search results: QCC will display a list of companies that match your search query. Look for the company you are interested in and click on its name to access its detailed information page.

6. Review company information: On the company information page, you will find various details about the company, such as its registration number, legal representative, registered capital, and date of establishment. This information can help you verify the legitimacy of the company.

7. Check company credit: Scroll down the page to find the “Credit Information” section. Here, you can view the company’s credit rating, credit code, and any records of legal disputes or administrative penalties. A good credit rating and a clean legal record indicate that the company is financially stable and trustworthy.

8. Examine certifications and qualifications: Look for any industry certifications or qualifications that the company may have, such as ISO certifications or CE marking. These certifications can serve as evidence of the company’s commitment to quality and compliance with industry standards.

9. Investigate company connections: QCC also provides information on a company’s shareholders, subsidiaries, and affiliated companies. By examining these connections, you can gain a better understanding of the company’s business network and potential partnerships.

10. Make an informed decision: Based on the information gathered from QCC, you can assess the creditworthiness and reliability of the fiber laser cutting machine manufacturer. This will help you make an informed decision when choosing a supplier or business partner in China.

How to use archive.org to check fiber laser cutting machine manufacturer business website history

Archive.org, also known as the Wayback Machine, is a digital archive of the World Wide Web that allows users to view the history of websites. To check the history of a fiber laser cutting machine manufacturer’s business website, follow these steps:

1. Visit archive.org: Open your web browser and go to the Archive.org website (https://archive.org/).

2. Locate the Wayback Machine search bar: On the homepage, you will find a search bar labeled “Wayback Machine” at the top of the page.

3. Enter the website URL: Type or paste the URL of the fiber laser cutting machine manufacturer’s business website into the search bar. Make sure to include the “http://” or “https://” prefix and press Enter.

4. View the website’s history: The Wayback Machine will display a calendar view of the website’s history, with blue or green circles on dates when the website was archived. The more circles, the more snapshots of the website are available.

5. Browse the snapshots: Click on a date with a circle to view a snapshot of the website on that day. You can navigate through the website’s pages as they appeared on that date, allowing you to see changes in content, design, and other elements over time.

6. Compare different snapshots: To compare the website’s history, open multiple snapshots in different browser tabs. This will allow you to easily switch between different dates and see how the website has evolved.

7. Analyze the website’s history: As you browse through the snapshots, pay attention to the following aspects:

a. Company information: Check for changes in the company’s name, address, contact details, and management team.

b. Product offerings: Look for changes in the range of fiber laser cutting machines offered, their specifications, and any new technologies introduced.

c. Customer testimonials and case studies: See if the company has added or removed any customer testimonials or case studies over time, which may indicate changes in their customer base or market focus.

d. Certifications and awards: Check for any new certifications or awards the company has received, which may indicate improvements in their manufacturing processes or product quality.

By following these steps, you can use Archive.org to gain valuable insights into the history of a fiber laser cutting machine manufacturer’s business website and make informed decisions about their credibility and reliability.

Why contact sourcifyChina.com get free quota from reliable fiber laser cutting machine manufacturer?

Contacting SourcifyChina.com to get a free quote from a reliable fiber laser cutting machine manufacturer is a smart move for several reasons. In today’s competitive market, it is crucial to find a trustworthy supplier that can provide high-quality products at reasonable prices. By reaching out to SourcifyChina.com, you can save time, money, and effort in your search for the perfect fiber laser cutting machine.

Firstly, SourcifyChina.com has a vast network of reliable manufacturers and suppliers in China. They have established relationships with these companies, ensuring that they only work with reputable businesses that meet their strict quality standards. By getting a free quote from them, you can be confident that you are dealing with a trustworthy manufacturer.

Secondly, SourcifyChina.com’s team of experts has extensive knowledge and experience in the industry. They understand the intricacies of fiber laser cutting machines and can help you find the best solution for your specific needs. By providing detailed information about your requirements, they can match you with the most suitable manufacturer, ensuring that you receive a product that meets your expectations.

Thirdly, getting a free quote from SourcifyChina.com can save you time and effort. Instead of spending countless hours researching and contacting manufacturers yourself, you can rely on their expertise to find the best supplier for you. This allows you to focus on other important aspects of your business, knowing that your fiber laser cutting machine needs are being taken care of.

Lastly, by obtaining a free quote from a reliable manufacturer through SourcifyChina.com, you can potentially save money. They can help you negotiate the best possible price for your fiber laser cutting machine, ensuring that you get the most value for your investment. Additionally, their knowledge of the market can help you avoid potential pitfalls and hidden costs that may arise when dealing with suppliers directly.

In conclusion, contacting SourcifyChina.com for a free quote from a reliable fiber laser cutting machine manufacturer is a wise decision. Their extensive network, industry expertise, time-saving benefits, and potential cost savings make them an invaluable resource for businesses looking to source high-quality fiber laser cutting machines.

Related products

food machinery

food machinery

©2023. sourcifychina.com All Rights Reserved.

-

- Home

- Retail Cheap Shop

- Wholesale Featured Pro

- Industries

- List

- Our China Suppliers list

- Auto Parts Suppliers

- Packaging Solution

- Stainless Steel Suppliers

- Steel Pipe Suppliers

- Solar Inverter China

- cable manufacturing

- cnc machining China

- Apparel and Accessories

- fabric manufacturing

- Machinery

- pump China

- Screw

- wigs custom

- valves manufacturing

- hair system custom

- heated gloves wholesale

- indoor lighting fixtures

- solor panel wholesale

- snow boots factory

- Products

- Manufacturing

- Guide

- Apparel / Fashion Accessories

- CNC Tools Valve Pump Parts

- Machinery China Equiment Sourcing Guide

- aac block manufacturers

- acrylic cutting machine

- automatic packing machine

- Auxiliary Equipment

- blister packing machine

- bricks manufacturing

- clay brick making machine

- feed pellet machine

- fly ash bricks machine sourcing guide

- paper bag making machine

- pellet machine

- plastic crusher machine

- pouchpacking machine

- stamping machine

- wood pellet machine

- Outdoor Sports

- Others Sourcing Guide

- FAQ

- About

- Contact

- Login

- Newsletter

- [email protected] whatsapp 8615951276160

- 供应商

Login

- →

- WeChat: 8615951276160