List Technical Parameters of “injection molding plastic”

Injection molding is a widely used manufacturing process for producing plastic products in large quantities at a low cost. During the process, molten plastic material is injected into a mold, where it cools and solidifies into the desired shape. The following are some of the technical parameters that are important in injection molding:

1. Melting point: The melting point of the plastic material is a critical parameter, as it determines the temperature at which the plastic material needs to be liquefied to be injected into the mold.

2. Melt flow index (MFI): MFI is a viscosity measurement that indicates how easily the plastic material can be processed. A higher MFI means that the material can flow more easily, making it easier to inject into the mold.

3. Mold temperature: The mold temperature is crucial in controlling the cooling rate of the plastic material. A higher mold temperature results in a slower cooling rate, while a lower temperature causes faster cooling.

4. Injection pressure: The injection pressure is the force needed to push the molten plastic material into the mold. It needs to be precise and consistent to ensure that the product is of high quality and uniform.

5. Cooling time: The cooling time is the amount of time needed for the plastic material to solidify in the mold. It needs to be optimized to ensure that the product retains its shape and doesn’t deform.

6. Clamping force: The clamping force is the force exerted by the molding machine to keep the mold closed during the injection and cooling process. It needs to be strong enough to prevent any leaks or defects.

7. Wall thickness: The wall thickness of the product is an essential factor in injection molding, as thin walls can lead to warping and deformation.

8. Gate location: The gate is the point at which the molten plastic flows into the mold. The gate location needs to be carefully selected to ensure that it is easy to remove the finished product from the mold.

Overall, the success of injection molding depends on a variety of technical parameters that need to be carefully controlled and optimized to produce high-quality plastic products efficiently.

List Product features of “injection molding plastic”

Injection molding plastic is a versatile process that is commonly used to produce large quantities of products. In this process, molten plastic is injected into a mold cavity where it solidifies to form a finished product. The product features of injection molding plastics are numerous, ranging from strength and durability to flexibility and surface finish.

1. Accuracy: Injection molding plastic ensures high accuracy in the production of parts and components. The molds are designed with precision, ensuring that the finished product is accurate in terms of dimensions, shape, and appearance.

2. High Strength: Injection molded plastics exhibit high strength and durability. The process ensures that the plastic molecules are tightly packed, increasing the strength and durability of the final product.

3. Cost-effective: This manufacturing process is cost-effective for large quantities of products. Injection molding plastic allows for mass production of identical parts and components, which drives down the unit cost of each piece.

4. Wide range of materials: Injection molding plastic can be used with a wide range of materials. Some of the commonly used materials include thermoplastic, thermosetting plastic, and elastomers.

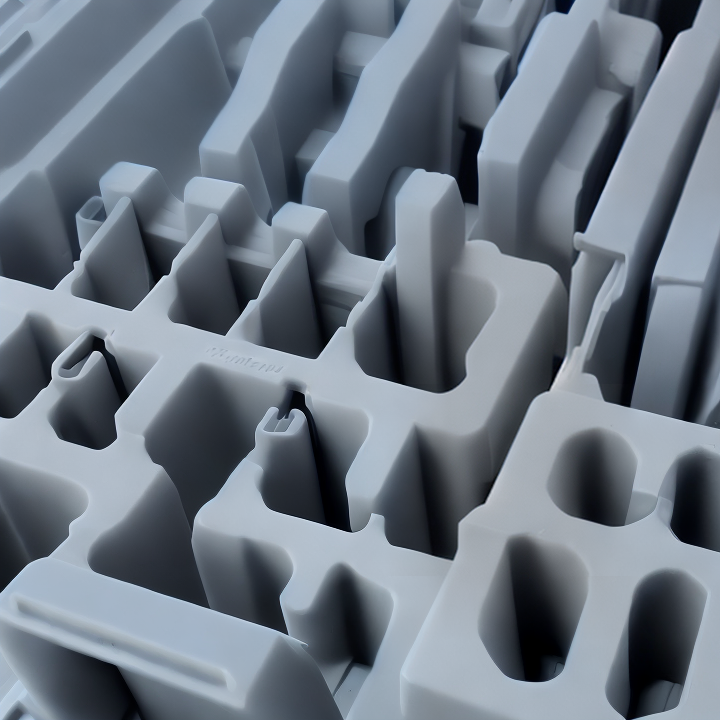

5. Complex geometries: Injection molding plastic can create parts with complex geometries that are difficult to achieve with other manufacturing processes. The molds can be designed to produce intricate shapes and contours that meet the requirements of the part design.

6. Variety of surface finishes: Injection molding plastic can provide various surface finishes to the product, depending on the requirements of the application. These surface finishes include glossy, matte, textured, or even metallic.

7. Excellent repeatability: Injection molding plastic ensures excellent repeatability, which means that every part produced will be identical to the rest. This is crucial for products that require precise tolerances and consistency.

8. Environmentally friendly: Injection molding plastic is an environmentally friendly process compared to other manufacturing processes. This is because it involves minimal waste generation, especially when compared to subtractive manufacturing processes like machining.

In conclusion, injection molding plastic is a highly versatile and efficient manufacturing process that provides a wide range of product features. The process offers accuracy, strength, cost-effectiveness, complexity, surface finishes, repeatability, and environmental benefits, making it a popular choice for the production of components and parts for various applications.

List Application of “injection molding plastic”

Injection molding plastic is a versatile manufacturing process commonly used in the production of various plastic products ranging from automotive parts to consumer goods. This process involves melting plastic pellets, injecting them into a mold, and allowing them to cool and solidify. Below are some of the applications of injection molding plastic:

1. Automotive Parts: Injection molding plastic is widely used in the production of various automotive parts such as dashboards, bumpers, caps, and handles. The use of injection molding plastic in the automotive industry is preferred because it’s lightweight, durable, and can be easily molded into complex shapes.

2. Medical Devices: Injection molding plastic is used in the production of various medical devices such as syringes, IV sets, and tubing. The use of injection molding plastic in the medical industry is preferred since it’s cost-effective, has a high level of precision, and can be sterilized without any damage.

3. Packaging: The process of injection molding plastic is widely used in the production of various packaging products such as containers, lids, and caps. Because plastic is lightweight and durable, many food and beverage companies prefer using it to package their products.

4. Consumer goods: Injection molding plastic is commonly used in the production of various consumer goods such as toys, appliances, and electronic devices. The use of injection molding plastic in the consumer goods industry is preferred because it produces products that are cost-effective, durable, and have a high level of aesthetic appeal.

5. Aerospace: Injection molding plastic is also used in the aerospace industry, particularly in the production of lightweight components such as brackets and housings. The use of injection molding plastic in the aerospace industry is preferred since it produces products that are cost-effective, strong, and can be easily molded into complex shapes.

In conclusion, Injection molding plastic is a widely used manufacturing process that offers cost-effective and efficient solutions for producing high-quality products. The versatility of this process makes it useful in various industries, including automotive, medical, packaging, consumer goods, and aerospace.

List Various Types of “injection molding plastic”

Injection molding is a popular manufacturing process used to create plastic products of different shapes and sizes. It involves injecting molten plastic into a mold cavity to produce a solid product or component. Here are some of the common types of injection molding plastics used in this process:

1. Acrylonitrile Butadiene Styrene (ABS): This plastic is known for its toughness, stability, and impact resistance, making it ideal for products that require durability like car parts, toys, and electronic housings.

2. Polypropylene (PP): PP is a versatile thermoplastic used in a variety of applications such as automotive, packaging, and medical products. It is known for its resistance to chemicals, fatigue, and thermal stress.

3. Polyethylene (PE): PE is used in the manufacturing of plastic bags, wire insulation, and other products where flexibility, toughness, and chemical resistance are required.

4. Polystyrene (PS): PS is an inexpensive, lightweight, and rigid plastic used in product packaging and disposable products like cutlery and plates.

5. Polycarbonate (PC): PC is a strong, durable, and transparent plastic used in the manufacturing of CDs, DVDs, safety glasses, and automobile components.

6. Nylon (PA): Nylon is a thermoplastic material that is known for its strength, toughness, and abrasion resistance. It is used in gears, bearings, and other high-stress applications.

7. Polyvinyl Chloride (PVC): PVC is a versatile plastic used in everything from construction materials to medical packaging and electrical cable insulation. It is known for its durability, stability, and resistance to impact and chemicals.

8. Polyphenylene Oxide (PPO): PPO is a high-performance thermoplastic used in components that require high heat resistance and dimensional stability, such as automotive parts, electrical connectors, and household appliances.

Each type of injection molding plastic has its own unique properties and advantages, making it suitable for specific applications. Manufacturers must choose the right type of plastic for their product to ensure that it meets all functional requirements while being cost-effective.

List The Evolution history of “injection molding plastic”

Injection molding plastic has come a long way since its introduction in the late 19th century. The process started with the use of wax and metal molds in the late 1800s, which were limited in size and shape and could not be produced in large quantities. In the early 20th century, the invention of Bakelite, the first synthetic plastic, led to the first commercial use of injection molding. This allowed for the mass production of small, complex parts.

In the 1930s, the introduction of thermoplastics, including polystyrene and polycarbonate, expanded the possibilities of injection molding. The process became faster and more reliable, leading to the production of larger and more complex parts. In the 1950s, the development of polypropylene further improved the process, allowing for even larger and more intricate parts to be made.

The 1960s saw the introduction of computer technology, which revolutionized injection molding. The use of computers allowed for precise control of temperature, pressure, and injection speed, resulting in higher quality and consistency. This also enabled the production of more complex and precise parts, including those with varying thickness and geometry.

In the 1980s and 1990s, advancements in material science led to the development of new high-performance plastics that could withstand higher temperatures and stress. This allowed for injection molding to be used in more industries, including automotive and aerospace.

In recent years, the focus has shifted to reducing waste and environmental impact. This has led to the development of biodegradable and recycled plastics that can be used in injection molding.

Today, injection molding is a vital component of manufacturing, providing efficient and cost-effective production of a wide range of parts. The process continues to evolve, with new technologies, materials, and processes constantly being developed to improve efficiency, precision, and sustainability.

List The Process of “injection molding plastic”

Injection molding plastic is the process of producing plastic products by melting and injecting raw plastic materials into a mold at a high pressure. This process is widely used to manufacture a wide range of items such as toys, automotive parts, containers, and medical devices.

Firstly, the mold is created by designing and engineering an original product and creating a 3D model using software. The mold is then created by using a CNC machine or other cutting methods. The mold can be made from various materials such as steel or aluminum depending on the product’s requirements.

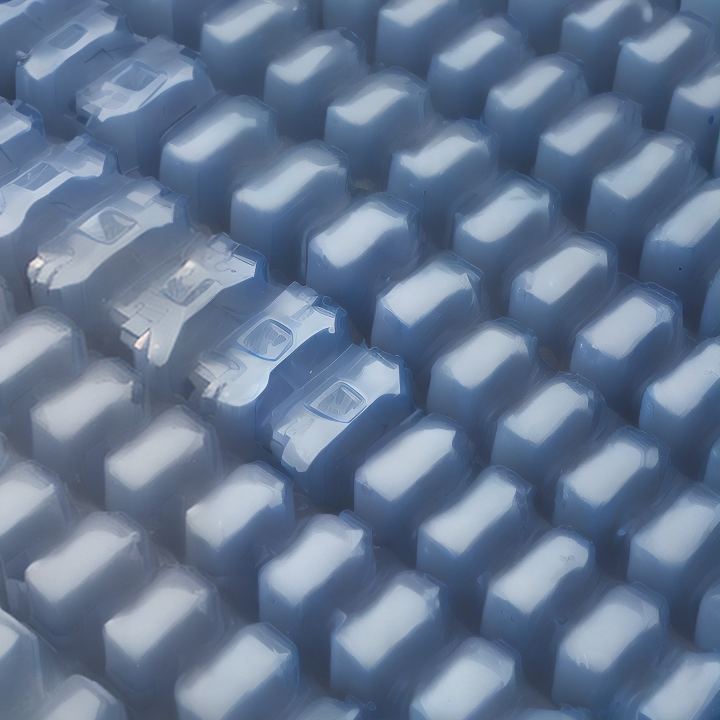

The next step is to select the appropriate plastic material to be used in the product. Different plastics have different properties, so choosing the right one is important. The plastic pellets are fed into the injection molding machine’s hopper where they are melted down to a liquid state.

The liquid plastic is then injected into the mold under high pressure. The mold is clamped shut, and the plastic is cooled and solidifies inside the mold. The mold is then opened, and the final product is ejected out.

Finally, the product is inspected for any defects or imperfections that may have occurred during the process. These can be fixed or removed, and then the product is ready for packaging and distribution.

Injection molding plastic is a cost-effective method of producing high volumes of products with precision and consistency. It is a complex process that requires skilled professionals, advanced equipment, and proper quality control measures to ensure that the final product meets the required specifications.

How to use “injection molding plastic”

Injection molding plastic is a popular method used to manufacture a wide range of products, including toys, automotive parts, packaging materials, medical devices and many more. The process involves feeding plastic pellets into a heated barrel, where they are melted and injected into a mold cavity. Once the plastic cools, it solidifies and takes the shape of the mold, producing a finished product.

To begin the process, the plastic pellets are poured into the hopper of the injection molding machine. The pellets flow down through the barrel and are heated to the appropriate temperature for melting. The molten plastic is then injected into the mold cavity through a nozzle. The mold is typically made from steel or aluminum and has two halves that are clamped together.

The mold is cooled either by circulating water through it or by cooling the mold with compressed air. Once the plastic has cooled and solidified, the mold is opened and the finished product is ejected.

Injection molding offers several advantages over other manufacturing processes. It allows for high levels of precision and consistency, making it possible to produce complex shapes with tight tolerances. The process is also highly efficient and can produce a large number of parts quickly and at a low cost.

There are several factors that can impact the quality and success of injection molding, including the type of plastic used, the design of the mold, and the settings of the injection molding machine. It is important to carefully consider these factors and work with experienced professionals to ensure optimal results.

In summary, injection molding plastic is a versatile and widely used manufacturing process that offers many benefits. By using the right materials and techniques, it is possible to produce high-quality products efficiently and cost-effectively.

List Properties of “injection molding plastic”

Injection molding is a widely used process in the manufacturing of plastic parts. It involves melting plastic raw materials, then injecting them into a mold under high pressure and temperature to create the desired shape. Here are some properties of injection molding plastic:

1. Versatility: Injection molding can produce parts with complex shapes and designs, making it suitable for a wide range of products, from small toys to large automotive parts.

2. Strength: Injection molding plastic parts are often strong and durable. The materials used in the process can withstand high temperatures, impact, and wear, making them ideal for parts that need to withstand harsh conditions.

3. Cost-effectiveness: Injection molding is a cost-effective way to produce plastic parts in large quantities. This is because the process can be highly automated and can create multiple identical parts simultaneously.

4. Consistency: Injection molding can produce parts with consistent quality and dimension. This is because the process is highly controlled, and the molds used are typically made to exact specifications.

5. Variety of materials: Injection molding can use a wide variety of plastic materials, including thermoplastics, thermosets, and elastomers. This allows manufacturers to choose the material that best suits the required properties of the finished part.

6. Surface finish: Injection molding can produce parts with a smooth, polished surface finish, which can reduce the need for post-production finishing processes.

7. Sustainability: Injection molding allows for the use of recycled plastic materials, making it an eco-friendly production method.

In conclusion, injection molding plastic has a wide range of properties that make it a popular choice for manufacturers. Its versatility, strength, cost-effectiveness, consistency, variety of materials, surface finish, and sustainability make it an attractive option for producing plastic parts.

List “injection molding plastic” FAQ

1. What is injection molding plastic?

Injection molding plastic is a manufacturing process used to produce plastic products in large quantities. The process involves injecting molten plastic into a mold cavity, where it cools and solidifies, taking the shape of the cavity.

2. What types of plastics can be used in injection molding?

In principle, any thermoplastic material can be used for injection molding. The choice of material largely depends on the application and the desired properties of the final product. Common plastics used in injection molding include polystyrene, polyethylene, polypropylene, PVC, ABS, and nylon.

3. What is the typical process for injection molding plastic?

The injection molding process typically involves the following steps: (1) melting the plastic pellets; (2) injecting the molten plastic into a mold; (3) cooling the mold to solidify the plastic; (4) opening the mold and ejecting the finished product.

4. What are the advantages of injection molding plastic?

Injection molding has several advantages over other plastics manufacturing processes, such as high production efficiency, high accuracy, and repeatability. It also enables the production of complex and detailed shapes that are difficult to achieve using other processes.

5. What is the cost of injection molding plastic?

The cost of injection molding plastic varies depending on several factors, such as the complexity of the mold, the type of plastic material used, and the quantity of parts produced. Overall, injection molding tends to be a cost-effective manufacturing process for large quantities of plastic parts.

6. What are some common applications for injection molding plastic?

Injection molding plastic is used to produce a wide range of products, such as automotive parts, medical devices, packaging materials, toys, and household appliances. Essentially, any product that can be made from plastic can potentially be produced using injection molding.

7. What is the typical lead time for injection molding plastic?

The lead time for injection molding plastic varies depending on the complexity of the mold, the quantity of parts needed, and the availability of material. A typical lead time is around 4-8 weeks, although this can be shorter or longer depending on the specific project.

8. Can injection molding plastic be used for prototyping?

Injection molding can be used for prototyping, but typically involves the creation of a prototype mold. This can be more expensive than other types of prototyping, but can provide a more accurate representation of the final product.

9. What are some potential challenges of injection molding plastic?

Injection molding can be a complex process that requires careful design and engineering. Some potential challenges include warping, flash, sink marks, and parting lines. However, with proper design and attention to detail, these issues can be minimized or eliminated.

10. What is the typical lifespan of an injection molding mold?

The lifespan of an injection molding mold can vary greatly depending on the type of material used, the complexity of the mold, and the conditions under which it is used. A well-designed mold can last several hundred thousand cycles or more, while less durable molds may only last a few thousand cycles.