List Technical Parameters of “bottle packing machine”

The bottle packing machine is a tool used for the automated filling, sealing and labelling of bottles of various sizes and shapes. This machine is designed to increase the efficiency of the packing process, reduce human error and improve the overall quality of the packaged product. The following are some of the technical parameters of a bottle packing machine:

1. Production capacity: This parameter refers to the number of bottles that can be filled, sealed and labelled per hour. The capacity of a bottle packing machine can range from a few hundred bottles per hour to thousands of bottles per hour depending on the machine’s design.

2. Filling capacity: The filling capacity of a bottle packing machine refers to the volume of liquid that can be filled into a bottle. This parameter is important because it determines the accuracy and consistency of the filled product.

3. Bottle size range: The bottle size range is a crucial parameter that determines the types of bottles that can be packed by the machine. Bottle packing machines come in different sizes, and each machine is designed to handle specific bottle sizes.

4. Power consumption: The power consumption of a bottle packing machine is a significant parameter that determines the operating costs of the machine. This parameter is essential to consider when selecting a machine because it affects the overall profitability of the process.

5. Operating speed: The operating speed of the machine refers to how fast the machine can perform its functions. The higher the operating speed, the more bottles can be processed within a given time frame.

6. Material type: The material type used to construct the machine determines the strength and durability of the machine. High-quality materials ensure that the machine can withstand the rigours of the packaging process, reducing the chances of breakdowns and maintenance costs.

7. Control system: The control system of the machine refers to the software that runs the machine. This parameter determines how effective the machine is in controlling the filling, sealing and labelling process, ensuring that the packaging process is error-free and meets the required quality standards.

8.

List Product features of “bottle packing machine”

A bottle packing machine is an essential piece of machinery for various industries where products need to be packaged in bottles. These machines are designed to automate the packaging process, which increases production efficiency while reducing labor costs. Here are some of the product features of a bottle packing machine:

1. High capacity: Bottle packing machines have a high filling capacity that can accommodate a large number of bottles at once, improving production efficiency.

2. Customizable: These machines are customizable to fit different bottle sizes, shapes, and capacities, making them versatile for various products, including pharmaceuticals, food, and beverages.

3. Easy-to-use: A bottle packing machine comes with easy to use control panels that allow operators to adjust settings, monitor performance, and quickly diagnose any malfunctions.

4. Quick setup: These machines are quick to set up, saving you valuable production time and ensuring that you hit the ground running.

5. High accuracy: A bottle packing machine ensures that the products are accurately measured, reducing waste, and avoiding rework.

6. Quality assurance: Using a bottle packing machine ensures consistent and high-quality packaging, making your products stand out in the market.

7. Durability: Bottle packing machines are built to last, with strong materials that can withstand wear and tear from constant use.

8. Sanitary: A bottle packing machine is designed for easy cleaning, maintaining high levels of hygiene that are essential for ensuring the safety of consumers.

9. Cost-effective: Investing in a bottle packing machine may seem expensive at first, but it is cost-effective in the long run, as it reduces labor costs, improves production efficiency, and eliminates the need for repetitive manual tasks.

In summary, a bottle packing machine is a complex piece of machinery designed to automate the packaging of bottles in various industries. Its customizable and versatile design caters to different bottle sizes and capacities, while high accuracy and quality assurance offer consistent and high-quality packaging. These machines are easy to use, quick to set up, durable, hygienic

List Application of “bottle packing machine”

Bottle packing machines are essential equipment in the manufacturing of bottled products such as beverages, pharmaceuticals, and personal care products. The machines automate the packaging process whereby the product is bottled, capped, and labeled. The advantages of using bottle packing machines include faster production rates, precision, consistency, and cost efficiency. Some of the major applications of bottle packing machines are discussed below:

1. Beverage manufacturing: Bottle packing machines are commonly used in the beverage industry to package various types of drinks such as soda, juice, water, and energy drinks. The machines can handle different types of bottles and caps, and are equipped with advanced features such as filling stations, labeling systems, and bottle inspection machines.

2. Pharmaceutical manufacturing: In the pharmaceutical industry, bottle packing machines are used in the packaging of tablets, capsules, and liquid medicines. These machines are designed to meet strict standards of hygiene and precision to ensure that the products are packaged in a sterile environment.

3. Cosmetic manufacturing: Bottle packing machines play a critical role in the cosmetics industry by automating the packaging of various personal care products such as lotions, shampoos, and perfumes. The machines are designed to handle different types of containers and are equipped with advanced labeling and capping systems.

4. Oil and lubricants manufacturing: Bottle packing machines are used in the oil and lubricants industry to package motor oil, hydraulic fluids, and other types of lubricants. The machines are designed to handle different types of bottles and caps and are equipped with high-speed filling and capping systems.

5. Food and condiments manufacturing: Bottle packing machines are used in the food industry to package products such as ketchup, mustard, and salad dressings. The machines are equipped with advanced filling and capping systems and are designed to handle different types of bottles and caps.

In conclusion, bottle packing machines are essential equipment in the manufacturing of various types of bottled products. They provide fast, precise, and consistent packaging, thereby improving product quality and reducing production costs

List Various Types of “bottle packing machine”

1. Automatic Bottle Filling Machine: It fills bottles with liquid products like water, juice, milk, soft drinks, etc. using a pump or gravity tank. The process is automated and accurate, resulting in consistent filling levels.

2. Labeling Machine: It applies labels on bottles accurately using sensors and printing mechanisms. The label can be a sticker or heat-shrink sleeve covering the entire bottle. The labeling machine is useful in mass production and branding.

3. Capping Machine: It seals the bottle with a cap or cork, ensuring the content stays secure and fresh. The capping machine can be manual, semi-automatic, or fully automatic, depending on the production rate.

4. Carton Packer: It packs bottles into cartons or boxes in a predetermined pattern. The carton packer increases efficiency and reduces labor costs by automating the cartonization process.

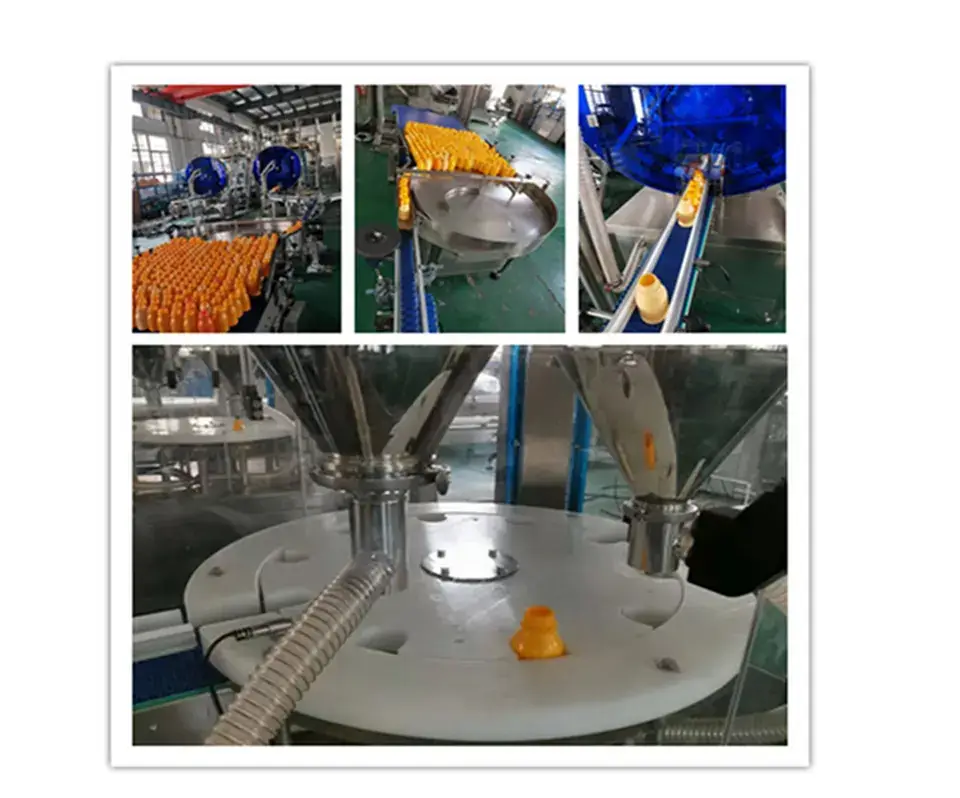

5. Bottle Unscrambler: It arranges bottles in the correct orientation and pattern for the next stage of production, such as the filling or labeling process. The bottle unscrambler is useful in sorting and organizing bottles of different shapes and sizes.

6. Shrink Wrapping Machine: It wraps bottles with a plastic film and shrinks it using heat or steam. The process creates a tight, protective layer around the bottle that prevents damage during transport or storage.

7. Inspection Machine: It checks the quality of filled and labeled bottles, looking out for defects, leaks, or wrong labeling. The inspection machine ensures that only bottles that meet the set standards proceed to the next stage.

In conclusion, bottle packing machines come in various types that serve different functions in the production process. They automate the production process, increase efficiency, reduce labor costs, and improve the quality of the finished product.

List “bottle packing machine” FAQ

Q: What is a bottle packing machine?

A: A bottle packing machine is a piece of equipment used in industries to automate the process of packaging bottles with various types of products, such as beverages, cosmetics, and pharmaceuticals.

Q: What types of bottle packing machines are available in the market?

A: Several types of bottle packing machines are available in the market, such as automatic bottle packing machines, semi-automatic bottle packing machines, and stand-alone bottle packing machines.

Q: What are the advantages of using a bottle packing machine?

A: The advantages of using a bottle packing machine are increased efficiency, higher productivity, improved quality, reduced labor cost and time, and greater accuracy.

Q: How does a bottle packing machine work?

A: A bottle packing machine works by automatically feeding bottles into the machine, filling them with the product, and sealing them with a cap or lid. The process can be fully automated or semi-automated, depending on the type of machine.

Q: What are the factors to consider while choosing a bottle packing machine?

A: The factors to consider while choosing a bottle packing machine include the type of bottle and product, the desired production capacity, the level of automation required, the space available, and the budget.

Q: Can a bottle packing machine handle different types of bottles and products?

A: Yes, most modern bottle packing machines are designed to handle different types of bottles and products, such as glass, plastic, and metal bottles, and liquid, powder, and solid products.

Q: How can one ensure the quality of the packaged bottles with a bottle packing machine?

A: One can ensure the quality of the packaged bottles by choosing a machine with high accuracy and precision, checking the cleanliness of the machine regularly, testing the finished products for defects, and following the manufacturer’s guidelines for maintenance.

Q: Is the installation of a bottle packing machine complicated?

A: The installation of a bottle packing machine can be complicated, depending on the machine’s complexity and the

List The Evolution history of “bottle packing machine”

The evolution of bottle packing machines dates back to the beginning of the 20th century when the first automated filling machine was invented. It was a mechanical machine that used gravity to fill bottles with liquid products. The machines were relatively slow with a manual process that required a lot of manual labor.

In the 1950s, pneumatic technology was introduced, which allowed for higher speed and accuracy in filling bottles. These machines used compressed air to fill bottles and had an increased range of bottle shapes and sizes.

In the 1970s, electronic control systems were introduced, enabling machines to be more precise and automated. The machines were computer-controlled, and the production speed was ramped up to 300 bottles per minute.

The 1990s saw the introduction of servo-controlled systems in bottle packing machines. This new technology allowed machines to operate more quietly, with a higher speed, and with more accuracy than before. With the increasing demand for continuous operation and flexibility, multi-lane machines were developed that had six to eight lanes and could handle up to 1,200 bottles per minute.

In the 2000s, robotic technology was incorporated to develop more sophisticated machines, which could handle high-speed multipacks, sleeve labeling, and other functions. The robotic packaging machines could fill, cap and label bottles with speed and precision, and also had high-flexibility features that allowed quick and easy format changes.

Today, state-of-the-art bottle packing machines utilize the latest technology, such as vision inspection systems, to ensure quality control and continuously improve efficiency. Innovative features such as connectivity to the internet of things (IoT) and remote monitoring systems allow for real-time monitoring and adjustment of the machines. With this evolution, bottle packing machines have become an essential part of modern manufacturing processes.

List The Process of “bottle packing machine”

The bottle packing machine is an automated system that is used in the packaging industry to package bottled products. This machine is used to pack a variety of bottled products such as water, juice, milk, and soda, among others.

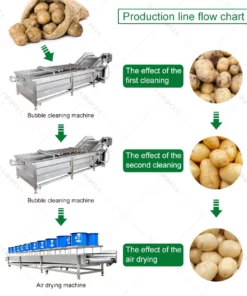

The process of the bottle packing machine can be broken down into five main steps. Below is a brief overview of each step:

Step 1: Bottle Loading

In this step, empty bottles are loaded onto the conveyor belt of the bottle packing machine. The conveyor belt moves the bottles through the machine, and they are positioned accordingly for the next step.

Step 2: Bottle Filling

Once the bottles are positioned correctly, the machine uses an automatic filling system to fill each bottle with the product. The filling system can be adjusted to measure the correct amount of product into the bottle.

Step 3: Bottle Capping

After the product is filled into the bottle, the machine applies the bottle caps automatically. The caps are placed on top of the bottle and secured tightly to prevent leakage and ensure freshness.

Step 4: Bottle Labeling

Once the caps are secured, the machine applies labels to the bottle. The labels can contain information such as the product’s name, brand, expiry date, and other details that may be required by law.

Step 5: Bottle Packaging

The final step in the process involves the completed bottles being packaged into boxes or cartons. The machine packages the bottles automatically by placing them into the containers and sealing them tightly.

In conclusion, the bottle packing machine is an essential piece of equipment in the packaging industry. The five-step process outlined above ensures that bottles are filled, capped, labeled, and packaged efficiently and accurately. This machine eliminates the need for manual labor, which helps to improve production efficiency, speed, and consistency while minimizing wastage.

List Properties of “bottle packing machine”

Bottle packing machines are an essential part of the manufacturing industry, where they are used to pack a variety of materials into bottles of different shapes and sizes. These machines are designed to handle a broad range of bottle sizes and speeds, from small bottles to larger ones, and from slow to fast moving lines. Typically, a bottle packing machine will have the following properties:

1. Material compatibility – The machine is built with materials that are compatible with the product to be packed. This ensures that the product is safe for consumption and extends its shelf life.

2. Bottle changeover – Bottle packing machines are designed to make it easy to change from one bottle configuration to another. This saves time and reduces downtime, allowing manufacturers to produce more.

3. Flexible – Bottle packing machines typically have a vast range of capabilities that allow them to handle different bottle shapes and sizes. The machine can be customized to meet specific requirements and increased production demands.

4. High-speed operation – Bottle packing machines are designed to work efficiently, at high speeds. These machines are typically equipped with advanced technology, which helps to prevent product spillage, breakage or damage.

5. User-friendly – Bottle packing machines are easy to use and operate. They have a simple interface that allows operators to monitor the machine’s performance, make adjustments as necessary, and resolve any issues that may arise quickly.

6. Efficient – Bottle packing machines are designed to pack more bottles in a shorter time frame, ensuring production goals are met without causing undue stress on the machinery.

7. Consistency – Bottle packing machines can pack a consistent volume of product into each bottle, ensuring that product quality is maintained from the first bottle to the last bottle in the production batch.

In conclusion, bottle packing machines play a crucial role in the manufacturing industry. The machine’s properties ensure that the production process runs smoothly, efficiently, and consistently, allowing manufacturers to produce high-quality products while meeting their production goals.

List Knowledge about “bottle packing machine”

A bottle packing machine, also known as a bottling machine, is an automated piece of equipment used in the packaging industry for the purpose of filling, capping, and labeling bottles. These machines are generally used to pack bottles with beverages, such as water, soda, juice, and alcohol, but can also be used for other liquids such as oil, shampoo, and cleaning solutions.

There are several different types of bottle packing machines, each with their own unique functions and features. These include rotary machines, linear machines, monoblock machines, and rinser/filler/capper machines.

Rotary machines operate by rotating a carousel of bottles past the various stations that fill, cap, and label them. Linear machines are similar but operate in a straight line instead of a carousel. Monoblock machines combine multiple functions into a single machine, such as filling, capping, and labeling in one unit. Rinser/filler/capper machines combine the stages of rinsing, filling, and capping in a single unit.

Bottle packing machines offer several advantages to businesses in terms of speed, accuracy, and cost-effectiveness. They are highly efficient and can fill and pack hundreds of bottles each minute. They are also highly precise, ensuring that each bottle is filled to the same level and capped correctly every time. Finally, they are cost-effective for businesses, as they require less labor and can operate continuously for long periods of time.

However, there are also some drawbacks to using bottle packing machines. They can be expensive to purchase and maintain, and may require a significant investment of time and resources to set up and maintain. Additionally, they may not be suitable for packaging certain products, such as those that are highly viscous or contain particulate matter.

Overall, a bottle packing machine is an essential piece of equipment for many businesses in the packaging industry. They offer several advantages in terms of speed, accuracy, and cost-effectiveness, and are able to handle large volumes of bottles efficiently.

How to use “bottle packing machine”

A bottle packing machine is a machine that is used to automatically fill and pack bottles with various types of products. These machines are commonly used in the food, beverage, pharmaceutical, and cosmetic industries. The primary purpose of this machine is to reduce the amount of manual labor required to pack products into bottles. The machine works by using various components such as a conveyor, filling system, capping system, and labeling system.

To use a bottle packing machine, the operator would need to make a few adjustments to the machine based on the size and type of the bottle being used. This can be done by adjusting the height of the conveyor and the filling system. Once these adjustments have been made, the operator can begin the filling process by loading the bottles onto the conveyor. The machine then fills the bottles according to the pre-set volume or weight settings.

Once the bottles are filled, the capping system comes into play. The machine places the cap on the top of the bottle and then uses a tightening mechanism to secure the cap in place. The machine can be set to tighten the cap to a specific torque, ensuring consistency across every bottle.

Finally, the labeling system can be used to place labels on the bottles. The labeling system can print and apply labels automatically or using a manual system.

The simplicity and efficiency of this machine make it an essential addition to any production line where packaging is required. It saves time, reduces costs, and ensures a consistent level of quality. That said, proper maintenance and regular cleaning of the machine are necessary to ensure functionality and longevity.

Terms “bottle packing machine”

A bottle packing machine is a type of machinery used to automate the process of packaging bottles. These machines are used in various industries, including pharmaceuticals, food and beverage, cosmetics, and household products. With the increasing demand for high production rates, consistent quality packaging, and improved efficiency, bottle packing machines are becoming popular among manufacturers.

The bottle packing machines come in different models and configurations, suitable for specific material types, packaging sizes, and speeds. The most common types of bottle packing machines include rotary filling machines, bottle capping machines, and labeling machines.

Rotary filling machines are used to fill bottles with liquid or semi-liquid products, such as syrups, creams, and oils. The rotary filling machines use a rotating platform where the bottles are placed and moved through the filling station, where the product is filled into the bottles.

Bottle capping machines are used to close the bottles after filling. These machines use different types of caps, such as screw caps, snap caps, and pumps, depending on the product and packaging requirements. Some bottle capping machines also include torque controls to ensure consistent and proper sealing.

Labeling machines are used to apply labels onto the bottles. These machines can apply different types of labels, including wrap-around labels, front-and-back labels, and sleeve labels. The labeling machines can also print information, such as batch numbers, expiry dates, and product codes, onto the labels.

Bottle packing machines offer several advantages, including improved efficiency, reduced labor costs, and increased production rates. These machines can also ensure consistent quality and reduce the risk of product contamination. Furthermore, bottle packing machines can be customized to meet the specific needs of manufacturers, including complying with regulatory standards and accommodating different packaging types.

In conclusion, bottle packing machines are essential equipment for manufacturers in the modern market. With the increased demand for automation and quality in packaging, the use of these machines is becoming a standard in various industries.