Benefits of “pouch filling machine”

Pouch filling machines are highly beneficial in a variety of industries that require efficient and precise packaging. Here are some of the primary benefits:

1. Time-saving: One of the main benefits of a pouch filling machine is that it can save significant time while filling and sealing pouches. In contrast, manual processes require a lot of time, human resource, and error-prone.

2. Increased accuracy: Pouch filling machines have highly advanced sensors that can regulate the amount of product per pouch. This ensures that each bag has precisely the right amount of product, thus reducing product waste and increasing accuracy.

3. Better shelf life: Pouch filling machines can create high-quality seals that help preserve the freshness of the product by keeping the pouch airtight. This ensures that the product stays fresh for longer, leading to reduced waste and increased shelf life.

4. Flexibility: Pouch filling machines can handle a range of pouch sizes and a range of products, including powders, liquids, and granules. This means businesses can be flexible with their production without the need for a separate machine for each product.

5. Increased productivity: Pouch filling machines require minimal labor and can run continuously for hours. This leads to increased productivity rates and greater output.

6. Cost-efficiency: Pouch filling machines can reduce the overall cost of packaging as it requires less labor, reduces wastage, and ensures that the right amount of product is used per pouch.

7. Compliance with safety and health regulations: Pouch filling machines have integrated safety features that ensure compliance with safety and health regulations, avoiding any risk of contamination or injuries to workers.

8. Consistency: Pouch filling machines help maintain product consistency by providing an accurate measure of the product in each pouch, preventing variances in the quantity and quality.

9. Environmental impact: Pouch filling machines enable packaging that consumes fewer materials and generates less waste, contributing to the reduction of the carbon footprint of businesses.

Overall, the benefits of a pouch filling machine

List Technical Parameters of “pouch filling machine”

A pouch filling machine is an automated packaging equipment used for filling and sealing different types of pouches with different materials such as liquid, paste, powder, and granules. The technical parameters of a pouch filling machine are vital as they determine the machine’s efficiency, capacity, and speed. Here are some technical parameters of a pouch filling machine:

1. Filling speed: The filling speed of a pouch filling machine is determined by the size and complexity of the pouch, the viscosity of the material being filled, and the filling mechanism used.

2. Pouch size: Pouch filling machines can handle different pouch sizes, and the machine’s capacity is determined by the maximum and minimum sizes of the pouch.

3. Filling accuracy: The accuracy of the pouch filling machine is crucial in ensuring consistent product quality. Errors in filling accuracy can lead to underfilled or overfilled pouches, which can be harmful to customers and damage the reputation of the manufacturer.

4. Filling volume: The volume of the pouch being filled depends on the required quantity, and the machine’s capacity should match the desired volume.

5. Materials compatibility: The materials, including the pouch and filling material, must be compatible with the pouch filling machine. This ensures smooth filling, proper sealing, and extended machine lifespan.

6. Automation level: Pouch filling machines have varying levels of automation, from semi-automatic to fully automatic. The automation level determines the machine’s speed, accuracy, and flexibility.

7. Seal quality: The quality of the seal is essential in ensuring the product’s freshness and preventing leakage, contamination, or tampering. The pouch filling machine should provide consistent and secure seals.

8. Machine material: The construction material of the pouch filling machine affects the machine’s durability, resistance to rust and corrosion, and ease of maintenance.

9. Power consumption: The power consumption of the pouch filling machine is dependent on the machine’s size and complexity. Efficient machines consume less power and ultimately reduce production costs.

10. Machine size

List Product features of “pouch filling machine”

A pouch filling machine is a machine designed to fill and seal packages with a variety of products. It is widely used in food, pharmaceutical, and chemical industries, among others. This machine offers a high level of accuracy, speed, and reliability in packaging products.

Product features of a pouch filling machine include:

1. Versatility: The machine is designed to fill and seal different pouch sizes and shapes, making it suitable for a wide range of products.

2. High-speed filling: Pouch filling machines can fill up to 200 pouches per minute, increasing productivity and efficiency.

3. Integrated controls: The control system is intuitive and easy to operate. It allows you to change settings like volume, filling speed, and sealing temperature.

4. Precision filling: The machine’s filling system offers precise and consistent filling, with minimal product wastage.

5. Safety features: The machine has a variety of safety features, including an automatic shut-off system when the pouch is not sealed correctly or is missing.

6. Easy maintenance: The machine is designed for easy cleaning and maintenance, with conveniently placed access points to ensure quick and easy cleaning.

7. Durability: Pouch filling machines are made from high-quality materials, ensuring their durability and longevity.

8. Filling options: Pouch filling machines offer different filling systems like auger fillers, piston fillers, and volumetric fillers.

9. Reduced product contamination risks: The machines are designed to keep hygienic standards, reducing product contamination risks.

10. Customization options: Manufacturers can customize pouch filling machines, optimizing them to suit specific product and packaging needs.

In summary, pouch filling machines offer a host of features, making them an ideal solution for many industries in need of accurate and efficient packaging.

List Application of “pouch filling machine”

Pouch filling machines are revolutionizing the packaging industry, and they are being applied in numerous areas. The automatic pouch filling machines are designed to increase the speed of production, enhance product quality, reduce labor costs, and optimize production processes. Here are some applications of pouch filling machines:

1. Food Packaging: Pouch filling machines are extensively used in the food and beverage industry. They are used for packaging meat, fish, cereals, tea, coffee, spices, biscuits, and pulses, among others. These machines are designed to pack the products in sachets, stand-up pouches, zip-lock pouches, and pillow pouches.

2. Pharmaceutical Industry: Pouch filling machines are widely used in the pharmaceutical industry. They are used for packaging medical devices, tablets, capsules, syrups, and powders. The machines produce sterile packaging that offers protection against contamination, thus ensuring product safety.

3. Cosmetic Industry: Pouch filling machines are used for packaging cosmetics such as hair care products, lotions, creams, and gels. This packaging ensures that these products are well protected from contamination and oxidation.

4. Chemical Industry: Pouch filling machines are utilized in the chemical industry to pack powder, granules, and liquid products. The machines are capable of handling high volumes of products, thus increasing production efficiency.

5. Seeds and Fertilizer Industry: Pouch filling machines are used for packaging seeds and fertilizers. The machines ensure that the packaging is done accurately, reducing the chances of contamination of the seed and fertilizers.

6. Pet Food Industry: The pet food industry uses pouch filling machines for packaging pet foods. The machines are used to fill and seal stand up pouches or gusseted pouches, ensuring that the food is well packed and stored.

Overall, pouch filling machines are an integral part of modern production processes, making them necessary investments for many industries. They aid in reducing overhead costs, improving product quality, and enhancing production processes in various sectors.

List Various Types of “pouch filling machine”

Pouch filling machines are used to fill pouches with various types of products, such as powders, liquids, solids, granules, etc. There are several types of pouch filling machines designed for specific end-use applications. Here are some commonly used types:

1. Auger Filling Machines: These machines use an auger screw to measure and fill pouches with powders and granules. Auger filling machines are ideal for filling pouches with uniform consistency products.

2. Volumetric Filling Machines: These machines measure and fill pouches based on volume. They are ideal for filling pouches with liquid or semi-solid products.

3. Weighing Filling Machines: These machines accurately weigh the product and fill the pouches based on weight. They are commonly used for filling snack foods, nuts, and other products that require accurate weight measurements.

4. Vertical Form Fill Seal (VFFS) Machines: These machines create pouches from a flat roll of material, fill them with product, and then seal them. VFFS machines are used for filling a wide range of products, including powders, liquids, granules, and solids.

5. Horizontal Form Fill Seal (HFFS) Machines: These machines create pouches, fill them with product, and then seal them horizontally. HFFS machines are used for filling products that are more difficult to handle, such as fragile or sticky products.

6. Stick Pack Filling Machines: These machines create long, thin pouches that are ideal for single-serve products, such as sugar or creamer. Stick pack filling machines are often used in the food and beverage industry.

7. Pre-made Pouch Filling Machines: These machines are designed to fill pre-made pouches with product. Pre-made pouch filling machines are commonly used in the pharmaceutical and cosmetic industries.

In conclusion, pouch filling machines come in various types, each designed to suit specific products and end-use applications. Picking the right pouch filling machine

List “pouch filling machine” FAQ

1. What is a pouch filling machine?

A pouch filling machine is a machine used in packaging operations to fill pouches with a desired product, be it liquid, semisolid or solid substance.

2. What are the types of pouch filling machines?

There are several types of pouch filling machines, including vertical form fill and seal machines (VFFS), horizontal form fill and seal machines (HFFS), stick pack machines, and sachet filling machines.

3. What products can a pouch filling machine package?

A pouch filling machine can package a wide range of products, including food and beverages, cosmetics, pharmaceuticals, and chemical products.

4. How does a pouch filling machine work?

Pouch filling machines work by holding a roll of packaging film, forming a pouch from the material, filling the pouch with the product, and sealing the pouch before cutting it from the roll.

5. What is the production capacity of a pouch filling machine?

The production capacity of a pouch filling machine depends on the type and model of the machine, as well as the product characteristics. However, most machines can fill up to 150 pouches per minute.

6. What types of packaging materials can be used with a pouch filling machine?

Pouch filling machines can work with a range of materials, including laminated films, polyethylene (PE), polypropylene (PP), and foil.

7. What level of customization is possible with a pouch filling machine?

Pouch filling machines can be customized based on the packaging requirements of the product. For instance, some machines can be customized to fill different sized pouches or add additional printing and labeling features.

8. How can I maintain my pouch filling machine?

Maintenance of a pouch filling machine involves regular checks and cleaning, replacing worn parts, calibration, and ensuring there is a consistent supply of packaging materials.

9. How do I ensure the safety of my pouch filling machine?

To ensure the safety of the operator and the product, pouch filling machine manufacturers commonly

List The Evolution history of “pouch filling machine”

The evolution of pouch filling machines dates back to ancient times when simple containers were used for storing and transporting goods. However, the modern era of pouch filling machines can be traced back to the 19th century when the first mechanical filling machines were invented. These machines were manually operated, and their speed was limited.

In the early 20th century, new advancements in technology made it possible to introduce electrical and pneumatically operated filling machines. These machines had higher speeds and greater efficiency, allowing industries to improve their production rates.

In the 1950s, the first rotary pouch filling machine was introduced. This machine allowed for filling multiple pouches at once, thereby increasing production rates even further. Advances in technology continued, and in the 1970s and 1980s, computer-controlled pouch filling machines were introduced. These machines could be programmed for specific pouch sizes and production rates, further improving their efficiency.

Currently, the latest evolution of pouch filling machines is the introduction of fully automated systems. These machines can perform all aspects of the filling process, from pouch opening, filling, sealing, and packaging, with minimal human involvement. They are also equipped with advanced control systems that can monitor and adjust production rates in real-time, making them highly efficient and cost-effective.

Overall, the evolution of pouch filling machines has been driven by the need to improve production rates and efficiency while maintaining product quality and consistency. As technology continues to advance, we can expect pouch filling machines to become even more sophisticated and efficient.

List The Process of “pouch filling machine”

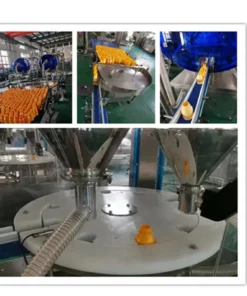

Pouch filling machines are used in a variety of industries to package and seal products in flexible packaging. The process of using a pouch filling machine involves the following steps:

Step 1: Preparation

The first step is to prepare the machine by making sure it is clean and free of any debris or residue. The pouches are also checked to ensure they are the correct size and shape for the product. The product is also prepared by weighing or measuring it to ensure the correct amount is added to the pouch.

Step 2: Filling

Once the machine is prepared, the pouches are loaded onto the machine and the product is added to the fill station. A filling system is used to ensure the correct amount of product is dispensed into the pouch.

Step 3: Sealing

After the pouch has been filled, it is sealed to prevent any leaks or contamination. A heat seal is applied to the edges of the pouch using a heat-sealing bar, which melts the material and creates a bond.

Step 4: Cutting

The pouches are then cut to their individual size using a cutting tool. This may be done in-line or off-line, depending on the machine and product.

Step 5: Inspection

Before the pouches are released from the machine, they are inspected for any defects or imperfections. This may be done visually or using automated systems, and any faulty pouches are discarded.

Step 6: Packaging and labeling

The pouches are then packaged and labeled according to their contents and any regulatory requirements.

Overall, the process of using a pouch filling machine is designed to be efficient and reliable, ensuring accurate filling and sealing of products in flexible packaging.

List Properties of “pouch filling machine”

Pouch filling machines are advanced technologically designed machines used for filling stand-up pouches, flat pouches, and spout pouches with liquid, granular, and powdered products. They are widely used in the food and beverage, pharmaceutical, cosmetic, and chemical industries.

1. Versatility: Pouch filling machines can be used for filling various types of pouches such as stand-up pouches, flat pouches, and spout pouches of different sizes and shapes.

2. Precise filling: Pouch filling machines are designed to fill pouches accurately and consistently at a high speed, making them ideal for large scale production.

3. Automatic operation: Pouch filling machines are equipped with automation mechanisms that make them easy to operate without the need for constant supervision.

4. Reduced wastage: Pouch filling machines are precise in their filling, which reduces product wastage by minimizing overflows and spills.

5. Sanitary design: Pouch filling machines are designed with hygiene in mind, which makes them easy to clean and maintain.

6. Product flexibility: Pouch filling machines can fill different types of products, including liquids, granules, and powders.

7. Reduced labor costs: Pouch filling machines require minimal human intervention, which lowers labor costs while increasing production output.

8. High-quality packaging: Pouch filling machines produce high-quality packaging which is visually appealing and guarantees product safety and shelf-life.

9. Customization: Pouch filling machines can be customized to meet specific production needs, such as filling speed, pouch size, and product viscosity.

10. Cost-effective: Pouch filling machines are a cost-effective investment that pays for itself in increased production output, reduced labor costs, and minimized product wastage.

List Knowledge about “pouch filling machine”

A pouch filling machine is a type of packaging equipment that is designed to fill and seal different types of flexible packaging. These machines can be used to fill a range of items such as food, beverages, cosmetics, chemicals, and pharmaceuticals. Pouch filling machines can be operated manually, semi-automated or fully automated, depending on the level of sophistication required.

The process of filling a pouch starts with the placement of the empty pouches on the machine. Next, the machine fills each pouch with the desired product dosage, which can be either volumetric or weight-based. Once filled, the pouches are sealed using different sealing technologies such as heat sealing, ultrasonic sealing or impulse sealing.

Pouch filling machines come in different types and configurations to meet different production needs. For instance, horizontal form-fill-seal machines consist of a long flat sealing unit that creates a seal and cuts the pouches from a film roll. On the other hand, rotary pouch filling machines have a rotating turret that fills and seals the pouches.

One of the benefits of using pouch filling machines is their ability to improve productivity and efficiency in the packaging process. Automated pouch filling machines can operate continuously without the need for manual intervention once the product and packaging materials have been loaded, thus maximizing throughput.

Another significant advantage of pouch filling machines is their flexibility, as they can handle different pouch sizes and shapes, as well as a range of filling materials. Besides, they offer excellent opportunities to customize packaging and branding, providing convenience, protection and freshness to the product.

Lastly, effective cleaning and maintenance of these machines can prolong their lifespan and ensure product integrity as they comply with hygienic standards. In summary, pouch filling machines have revolutionized the packaging industry, providing efficient, reliable and cost-effective solutions for most packaging requirements.

How to use “pouch filling machine”

A pouch filling machine is a type of packaging equipment that is used to fill different kinds of products in flexible packaging, such as pouches, sachets, and bags. These machines are commonly used in various industries such as food and beverage, pharmaceuticals, cosmetics, and household products to pack different types of products into pouches, bags or sachets for easy distribution and sale.

The machine can handle a variety of products, including powders, liquids, granular products, and other semi-solid substances. Pouch filling machines can fill pouches of different sizes and styles, including stand-up pouches, flat pouches, and gusseted pouches.

To use a pouch filling machine, the operator first needs to prepare the product for filling. The product is then placed into the hopper of the machine which leads to the dosing system. The dosing system dispenses a precise volume of the product into the pouch through a filling nozzle. The speed and rate of filling are customizable depending on the type and viscosity of the product.

The machine then seals the pouch to ensure that the product is securely packed and to protect it from external elements. The sealing process includes heat sealing, ultrasonic sealing, or other methods depending on the product and the type of pouch used. The filled pouches are then discharged through the conveyor belt for further processing or packing.

To ensure efficient operation and prevent downtime, regular maintenance and cleaning are necessary. The operator needs to clean and sanitize the machine regularly to prevent product contamination and ensure consistent product quality and safety.

In summary, a pouch filling machine is an essential packaging tool that can help businesses automate their packing process and improve efficiency, reduce waste, and ensure consistent product quality. By understanding how to use and maintain pouch filling machines correctly, businesses can improve their production capabilities and enhance their competitive edge.

Terms “pouch filling machine”

A pouch filling machine is a machine that is used to fill pouches with various products, such as liquid, solid, or semi-solid substances. These machines are designed to automate the filling process, making it more efficient and reliable. They are commonly used in the food and beverage industry, pharmaceuticals, cosmetics, and chemical industries.

The pouch filling machine works by using various mechanisms to dispense the product into the pouch. First, the pouches are opened and positioned to receive the product. Then, the filling mechanism is activated to dispense the product. The filling mechanism can be in the form of a nozzle or piston that dispenses the product into the pouch. The machine can fill a pre-measured amount of product or fill to a desired level within the pouch.

Some pouch filling machines are designed to fill a single pouch at a time, while others can fill multiple pouches simultaneously to increase productivity. The machines can also be customized to accommodate different pouch sizes and shapes, from small sachets to large bags.

In addition, pouch filling machines can be equipped with various features, such as automatic pouch loading, printing, labeling, and sealing for a complete packaging process. The machines can also be designed to handle different types of products, including hot or cold liquids, viscous materials, and powders.

Overall, pouch filling machines are an essential piece of equipment in modern packaging systems, providing efficient and reliable solutions for filling various products into pouches.