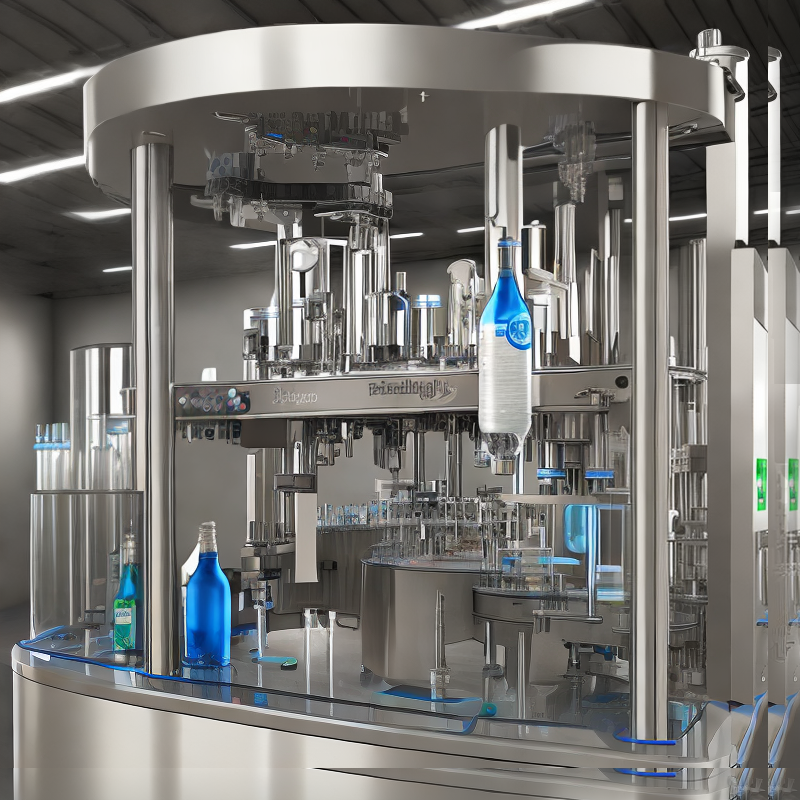

Bottle Filling Machine

A bottle filling machine is an important piece of equipment that can help businesses streamline their production processes and improve efficiency. There are numerous benefits to investing in a bottle filling machine, including:

1. Increased Production Efficiency – A bottle filling machine can automate the process of filling bottles, which can significantly increase production efficiency. This machine can fill a large volume of bottles quickly and accurately, which can save time and reduce labor costs.

2. Consistency – A bottle filling machine can ensure consistency in the amount of liquid in each bottle. This can help businesses maintain a high level of quality control and ensure customer satisfaction.

3. Versatility – Bottle filling machines can be used for a wide range of products, from water to juice, to pharmaceuticals, and even harsh chemicals. They also function well with different types of containers, including plastic bottles, glass jars, and cans.

4. Cost-Effective – A bottle filling machine is a cost-effective solution for businesses that require high-volume production as it can reduce the cost of manual labor required to fill bottles.

5. Customization – Many bottle filling machines can be customized to meet the specific needs of a business. This means that they can be adjusted to fill bottles of different sizes, shapes, and capacities.

6. Reduced Material Waste – A bottle filling machine can help reduce material waste by accurately filling bottles to the desired level, which can minimize the number of rejected bottles.

7. Space Saving – Bottling filling machines are compact in size which can save much-needed space in a production facility.

In conclusion, a bottle filling machine can help businesses increase production efficiency, save costs, maintain consistent quality control, and offer customization. They are also versatile in handling a wide range of products and containers, reduce material waste and save space. Investing in a bottle filling machine can improve a company’s bottom line and ensure higher quality products.

List Technical Parameters of “Bottle Filling Machine”

A bottle filling machine is used to fill bottles with liquid and is considered an essential component for any product-based industry that requires mass production. Here are the technical parameters of a bottle filling machine:

1. Capacity: This is the maximum amount of liquid the machine can fill in an hour or minute. The capacity of a machine usually ranges from 500 to 25,000 bottles per hour.

2. Filling Range: This is the volume range of liquid that the machine can fill into bottles. The range depends on the type of machine, and usually ranges from 50ml to 5 liters.

3. Number of Filling Heads: This refers to the number of filling nozzles on the machine. The number of heads ranges from 1 to over 50, depending on the speed and capacity of the machine.

4. Material: The parts of the machine that come into contact with the liquid must be made of food-grade stainless steel to prevent contamination of the product.

5. Control System: The modern bottle filling machines have a digital control system that enables the machine to adjust its parameters for different types of liquids and bottles. This allows for accuracy in filling volumes, speeds and other parameters.

6. Power Supply: Bottle filling machines require a three-phase power supply to operate. The power range depends on the size and capacity of the machine.

7. Bottle Types: Bottle filling machines can fill a range of bottle types, including glass and plastic bottles, and containers.

8. Filling Accuracy: Filling accuracy refers to the precision in which the machine can fill liquids into bottles. The filling accuracy depends mainly on the type of filling machine and the liquid being filled.

9. Cleaning System: The machine must have a cleaning system that ensures that the parts coming into contact with the liquid are cleaned thoroughly and don’t contaminate the next product batch.

Conclusion

Bottle filling machines are essential in the mass production of liquids in different industries, including the food and beverage industry, pharmaceutical industry,

List Product features of “Bottle Filling Machine”

A bottle filling machine is a piece of equipment designed to automatically fill bottles or containers with liquids, powders, granules, or small parts. Its key features include:

1. Versatility: Bottle filling machines can handle a range of container sizes, shapes, and materials, such as plastic, glass, or metal.

2. High speed: Most bottle filling machines are designed to work at high speeds, enabling continuous production runs and achieving production targets.

3. Accurate filling: The machines are programmed to fill the containers accurately to a specified volume, minimizing product waste and maintaining consistent quality.

4. Easy to operate: The machines are user-friendly and straightforward to operate, with touch screen interfaces and programming options.

5. Minimal maintenance: Bottle filling machines are designed to be low maintenance, with easy access for cleaning and sanitizing. The machines are also built with quality components that are designed to last.

6. Customization: The machines can be customized for various applications depending on the product being packaged, such as food, beverages, pharmaceuticals, or chemicals.

7. Safety features: The machines are built with various safety features such as emergency stop buttons, sensors, guarding and interlocking systems, to prevent accidents and injury.

8. Flexibility: Bottle filling machines can be easily adapted to different bottle sizes, filling volumes, and packaging configurations, making them ideal for small scale production or variable products.

9. Durability: The machines are designed for continuous use and built with high-quality components that are durable and resistant to wear and tear.

10. Cost-effective: By automating the filling process, the machines reduce labor costs and minimize product waste, resulting in a cost-effective solution for large scale production.

List Application of “Bottle Filling Machine”

A bottle filling machine is a type of automated equipment used in manufacturing process which has automated the process of filling bottles with fluids or powders. Below are some applications of a bottle filling machine:

1. Soft Drinks & Beverages Manufacturing: Filling machines are widely used in the soft drink and beverage production industry. They are used for filling carbonated drinks, juices, energy drinks, and other non-alcoholic beverages.

2. Pharmaceutical Industry: The pharmaceutical industry requires high-precision filling machines to fill medicine bottles with liquids, pills, and other drugs. Filling machines ensure accurate dosing and reduce the risk of error or contamination.

3. Cosmetics & Personal Care Industry: The cosmetics and personal care industry requires high-speed filling machines to fill products such as lotions, shampoos, conditioners, and soaps. The machines ensure perfect consistency and accurate filling of products.

4. Food and Sauce Industry: Filling machines are also used for filling foods such as mustard, ketchup, mayonnaise, and other sauces. They help to maintain the quality and safety of the products.

5. Chemical Industry: Chemical companies require filling machines to fill chemicals, oils, and lubricants in containers. These machines ensure safety and save time in the production process.

6. Bottled Water Production: Filling machines are used in bottled water production to fill and seal water bottles efficiently. They ensure consistency in the quantity of water added per bottle.

In conclusion, bottle filling machines offer numerous benefits that range from high precision filling accuracy to consistent production of high-quality products. They help to improve the speed and efficiency of the manufacturing process and reduce the costs associated with manual labour.

List Various Types of “Bottle Filling Machine”

Bottle filling machines are important equipment for many industries, ranging from food and beverage to pharmaceuticals and cosmetics. There are various types of bottle filling machines, each designed for specific applications. Some of the most common types are:

1. Gravity filling machine: This type of machine is typically used for filling low-viscosity liquids such as water, juice, and milk. It operates by using gravity to fill the bottle from a tank or reservoir.

2. Piston filling machine: This machine is used for filling thicker liquids such as sauces, creams, and lotions. It uses a piston that draws the liquid from a hopper and dispenses it into the bottle.

3. Overflow filling machine: This machine is used for filling containers to a precise level, typically used for bottles of perfume, shampoo, or other cosmetics. It overflows the liquid into the bottle until it reaches a certain level, after which it stops filling.

4. Auger filling machine: This machine is used for filling powders and granular products such as spices, coffee, and pharmaceutical powders. It uses a rotating screw to dispense the product into the bottle.

5. Vacuum filling machine: This machine is used for filling extremely low-viscosity liquids such as alcohol, essential oils, and solvents. It works by creating a vacuum in the bottle, which draws the liquid from a tank into the bottle.

6. Net weight filling machine: This machine is used for filling products by weight rather than volume, typically used for heavy products such as chemicals or pet food. It weighs the product as it is dispensed into the bottle.

7. Aseptic filling machine: This machine is used for filling products that require a sterile environment, typically used for pharmaceuticals and medical products. It uses special techniques to ensure the product remains sterile throughout the filling process.

In conclusion, choosing the right bottle filling machine depends on the type of product being filled and the production requirements.

List “Bottle Filling Machine” FAQ

Q: What is a bottle filling machine?

A: A bottle filling machine is a device that automates the filling of liquid substances into empty bottles or containers.

Q: What types of liquids can be filled using a bottle filling machine?

A: Bottle filling machines can be used to fill a wide range of liquids such as water, juice, oil, wine, and other beverages.

Q: How does a bottle filling machine work?

A: Bottle filling machines typically use a series of pumps, sensors, and valves to fill bottles accurately and consistently. The machine will first clean the bottle and then fill it with the desired amount of liquid before capping it.

Q: What are the benefits of using a bottle filling machine?

A: Using a bottle filling machine has several benefits, including increased efficiency, accuracy, and consistency in the filling process. This can result in cost savings, reduced waste, and improved quality control.

Q: What factors should I consider when choosing a bottle filling machine?

A: When choosing a bottle filling machine, consider factors such as the desired output speed, the type of liquid being filled, the bottle size and shape, and the necessary level of automation.

Q: Can a bottle filling machine be customized to fit my specific needs?

A: Yes, many bottle filling machines can be customized to fit specific needs, including different bottle sizes, shapes, and liquid types. A supplier can work with customers to design and build a machine that fits their specific requirements.

Q: How do I maintain and clean a bottle filling machine?

A: Bottle filling machines require regular cleaning and maintenance to ensure they operate smoothly and efficiently. This includes cleaning the system with the appropriate cleaning agents, replacing worn or damaged parts, and performing regular calibration and testing.

Q: How long does a bottle filling machine last?

A: The lifespan of a bottle filling machine can vary depending on factors such as the quality of the machine, the frequency and intensity of use, and the level of maintenance and care it receives.

List The Evolution history of “Bottle Filling Machine”

Bottle filling machines have been in existence for several years and have undergone numerous modifications to improve productivity and efficiency. The first bottle filling machine used gravity to fill bottles manually, and the operator had to place the bottle manually under the filler tube. The gravity concept was later developed into rotary fillers, which could fill several bottles at a time. The rotary filler has a wheel with several bottle holders that rotate as the bottles are filled. The rotary filler was however limited to the type of bottles it could fill.

With technological advancements in the 20th century, electronic bottle filling machines emerged. These machines used sensors and actuators to fill the bottles to the required level. They could also fill different types and sizes of bottles. The machines were more accurate and efficient and could fill several bottles simultaneously.

In the 21st century, the bottle-filling machine has evolved further to incorporate the concept of automation. Automation has made it possible to have high-speed filling with minimal supervision. Robotic arms have been integrated into the filling machines to ensure accurate positioning of the bottles under the filler tubes. In addition, the machines can detect and eject bottles that are not correctly positioned or those with defects.

Recent innovations in bottle filling machines have been geared towards reducing wastage and improving sustainability. The machines have been designed to be energy-efficient and can detect when the bottle is full to reduce spillage. Some machines have also been developed to fill bottles without compromising on the quality of the product. For instance, some machines can fill carbonated drinks without creating too much foam.

In conclusion, the evolution of bottle filling machines has been driven by the need to increase productivity, efficiency, and accuracy. The concept of automation, together with technology advancements, has led to the development of more advanced and sustainable filling machines.

List The Process of “Bottle Filling Machine”

The bottle filling machine is a mechanical equipment used for filling liquid substances into various types of containers such as bottles, jars, jars, and cans. The machine consists of several components that work together to achieve a completely automated process. Below is a simplified process of a typical bottle filling machine.

1. Bottle Feeding System

Empty bottles are loaded into the machine using a conveyor system. The feeding system determines the number of bottles to be filled at a time.

2. Bottle Rinsing

The bottles are washed with distilled water (or any other solvent as required) to maintain hygiene standards. The rinsing process removes any contaminants left in the bottles from the previous packaging cycle.

3. Filling

Liquid substances available in the factory are pumped to the filling machine tank from where the machine automatically fills the bottles based on a pre-set volume or weight. There are several types of filling heads that can be used depending on the nature of the product being filled.

4. Capping

Once the bottle filling process is complete, the downstream conveyor moves the bottles to the capping section. The machine automatically fits a cap on top of each bottle to prevent any leakages during transportation and storage.

5. Labeling

Finally, the labeled bottles are inspected using a quality control system to ensure accuracy in labeling, capping, and fill levels.

6. Packaging

The completed bottles are then packaged using shrink wraps, cartons or any other packaging materials as may be required for storage, transport or marketing purposes.

In summary, a bottle filling machine works seamlessly to reduce the need for manual labor and significantly increase production output. The efficiency and accuracy of the filling process also help to reduce the cost of production, making it an ideal machine for large scale beverage and chemical processing industries.

List Properties of “Bottle Filling Machine”

A bottle filling machine is a type of equipment used in the packaging industry to fill bottles with a variety of liquid products. The machine is designed to automate the process of filling containers of different shapes, sizes, and types, ensuring precision, consistency, and speed of operation. Some of the key properties of a bottle filling machine include:

1. Accuracy: Bottle filling machines are designed to deliver accurate and precise amounts of liquids into each container, thereby minimizing waste and ensuring that each bottle contains the correct amount of product.

2. Flexibility: A bottle filling machine can be used to fill bottles of different shapes, sizes, and types. This makes it a versatile option for companies that need to fill various types of containers.

3. Speed: A bottle filling machine can fill hundreds or even thousands of bottles per hour, depending on the type and size of the machine.

4. Sanitary: Bottle filling machines are typically made of stainless steel and are designed to be easily cleaned, which reduces the risk of cross-contamination and ensures the highest level of hygiene.

5. Ease of use: Bottle filling machines are designed to be user-friendly and easy to operate, with minimal training required to get started.

6. Safety: Bottle filling machines are equipped with various safety features, such as sensors to detect bottle jams and emergency stop buttons, to prevent accidents and injuries.

7. Low maintenance: Bottle filling machines are designed to be low maintenance, requiring minimal servicing and repairs.

In conclusion, bottle filling machines are an essential piece of equipment in the packaging industry, providing speed, accuracy, flexibility, and safety in the filling process.

List Knowledge about “Bottle Filling Machine”

A bottle filling machine is a type of packaging machinery used for filling various types of bottles with liquid or semi-liquid products. The machine is used in industries such as pharmaceuticals, cosmetics, food and beverage, chemical, and others. The main function of the machine is to fill bottles accurately, efficiently, and cleanly, thereby reducing wastage and contamination risk.

The machine uses various techniques for filling bottles, such as gravity filling, pressure filling, and vacuum filling. The selection of technique depends on the product viscosity, flow properties, and the desired fill level. The machine can fill bottles of different sizes, shapes, and materials, such as glass, plastic, metal, and others.

Bottle filling machines are designed with high-speed capabilities to increase productivity without sacrificing accuracy. They come in different configurations, including mono-block, rotary, linear, and inline, each with unique features to suit the production needs of different industries. Modern bottle filling machines are computer-controlled, ensuring precise filling volume and enabling the easy adjustment of fill parameters.

Additionally, most filling machines also come equipped with automatic cleaning systems, reducing downtime and ensuring product quality. Other advanced features include bottle counting, cap pre-treatment, and advanced safety controls.

In summary, bottle filling machines have revolutionized the packaging industry by automating the filling process, reducing manual labor, and optimizing output. These machines have become prevalent in many industries and continue to evolve with advancements in technology, making them more efficient, faster, and accurate.

How to use “Bottle Filling Machine”

A bottle filling machine is an automated device used in industries to fill bottles with liquids, such as water, juice, soda, or any other kind of beverage. The machine is designed to streamline the bottle filling process, ensuring efficiency and high production output. Below are the steps involved in using a typical bottle-filling machine:

1. Preparation: The first step in using a bottle filling machine is to prepare the bottles for filling. Ensure that the bottles are cleaned and ready for use.

2. Adjusting the machine: Adjust the machine to suit the bottle size and the type of liquid being filled. This is important because different bottles and liquids require different filling techniques.

3. Filling the bottles: Once the machine is set up, start filling the empty bottles with the liquid by placing them on the machine’s belt or conveyer. Ensure that the bottles are correctly positioned, and the filling process is precise, as this can affect the quality of the final product.

4. Capping the bottles: After filling the bottles, cap them using an automated capping mechanism. The machine can be programmed to apply the right amount of pressure to the cap to ensure a secure fit.

5. Labeling and packaging: The final step is to label and package the filled and capped bottles. The machine can be configured to apply labels automatically, and the bottles can be packaged in crates, cartons, or any other packaging material.

In conclusion, a bottle filling machine is a time-saving and efficient device that automates the process of bottle filling, capping, and packaging. It ensures a high production output, improved accuracy, and reduced labor costs. With these steps, one can utilize a bottle filling machine with ease.

Terms “Bottle Filling Machine”

A bottle filling machine is a type of industrial equipment used for packaging liquid products into bottles. This machine is commonly used in the food and beverage industry, pharmaceutical industry, and other manufacturing industries that deal with liquid products.

The machine works by automatically filling the bottles with liquid products such as water, juice, soda, beer, wine, and other similar products. The filling process can be done in different ways depending on the requirement of the product being filled. Some common methods include gravity filling, pressure filling, volumetric filling, and vacuum filling.

Gravity filling is the simplest and most common method used in filling machines. The liquid product is placed in a tank, and the machine uses gravity to fill the bottles. Pressure filling, on the other hand, uses pressure to force the liquid product into the bottles. Volumetric filling is used when the exact measurement of the liquid product needs to be precise. This method uses a specific volume of liquid to fill the bottles. Vacuum filling is used when the product is foamy or has air bubbles.

Bottle filling machines are designed to accommodate different bottle sizes and shapes. They come in different sizes and can fill bottles ranging from small to large sizes. Some machines can even fill up to 10,000 bottles per hour, making them an efficient and time-saving option for manufacturers.

In conclusion, bottle filling machines are essential equipment for industries that deal with liquid products. They are reliable, efficient, and cost-effective in filling bottles of different sizes and shapes. With their multiple filling methods, they ensure that the liquid product is filled accurately and efficiently.

Related products

food machinery

food machinery

food machinery

food machinery

food machinery

Request For Quote

Fill out the form below and we will contact you as soon as possible!

Useful Links & Infomation

©2023. sourcifychina.com All Rights Reserved.

-

- Home

- China Suppliers

- Our China Suppliers list

- auto parts china

- cable manufacturing

- cnc machining china

- fabric manufacturing

- Machinery

- pump china

- Screw

- wigs custom

- valves manufacturing

- hair system custom Hair Notion

- heated gloves wholesale

- indoor lighting fixtures

- solor panel bulk wholesale distributor

- yongle snow boots factory

- Products

- Sourcing Guide

- Manufacturing

- Apparel / Fashion Accessories

- caps manufacturing

- Denim Manufacturing Company Guide: Sourcing,Types, Applications, Benefits, Process, Price

- fabric manufacturing

- face masks supplier

- hoodies manufacturer

- knitwear manufacturing

- perfume bottle custom

- Ultimate Guide about Sportswear Manufacturing: Types, Applications,Sourcing,Process and More

- T-shirt Manufacturing Companies Guide: Sourcing,Types, Applications, Benefits, Process, Price

- wigs custom

- CNC Tools Valve Pump Parts

- Machinery China Equiment Sourcing Guide

- aac block manufacturers

- acrylic cutting machine

- automatic packing machine

- Auxiliary Equipment Guide: how to Use, Sourcing, Types, Applications, Benefits, Process

- blister packing machine

- bricks manufacturing

- clay brick making machine

- feed pellet machine

- fly ash bricks machine sourcing guide

- paper bag making machine

- pellet machine

- plastic crusher machine

- pouchpacking machine

- stamping machine

- wood pellet machine

- Outdoor Sports

- Others Sourcing Guide

- Apparel / Fashion Accessories

- FAQ

- About

- Contact

- Login

- Newsletter

- [email protected] whatsapp 8615951276160

Login

- →